© Wonders of World Engineering 2014-

Part 12

Part 12 of Wonders of World Engineering was published on Tuesday 18th May 1937, price 7d.

Part 12 includes a photogravure supplement showing The Shannon Power Scheme, illustrating the article on this project.

The Cover

The cover this week shows the pithead of the Horden Mine, one of the many pits in the county of Durham.

The cover complements the chapter on The Modern Coal Mine which begins in this part.

Contents of Part 12

Pioneering in Alaska and Yukon (Part 2)

The story of railway development in the north-west of the American continent. This chapter is concluded from part 11. It is the third article in the series on Railway Engineers at Work.

Conquest of the Dead Sea

Situated 1,292 feet below the level of the Mediterranean, the Dead Sea has a concentration of salts about eight times greater than that found normally in other seas. The waters of the Dead Sea are impregnated with salts such as potash, which are of great importance to various industries, and, indeed, to our everyday life. Plant has been installed on the shores of this natural chemical store to extract the wealth from the waters. This chapter describes how a great pipe lines was sunk to the bottom of the Dead Sea so that its waters could be pumped into huge evaporating pans to extract the salts.

Richard Trevithick

Although Trevithick is now known as the “father of the steam locomotive”, his work on the

development of steam engines, stationary as well as locomotive, was unrecognized until long after his death in 1833. This is the fifth article in the series on Makers of Engineering History.

The Shannon Power Scheme

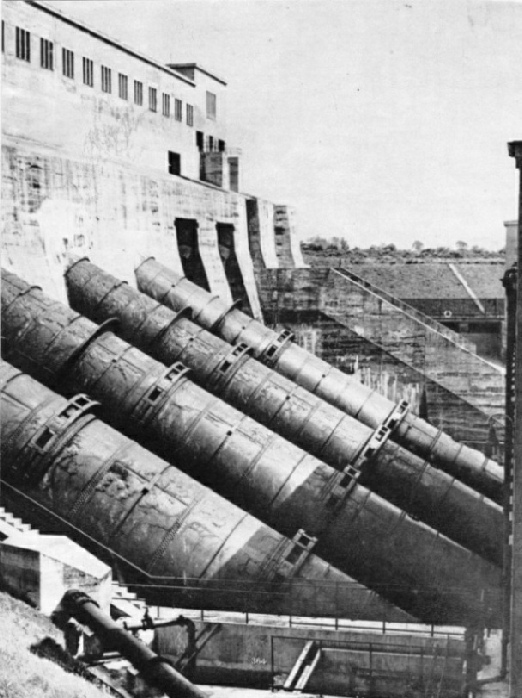

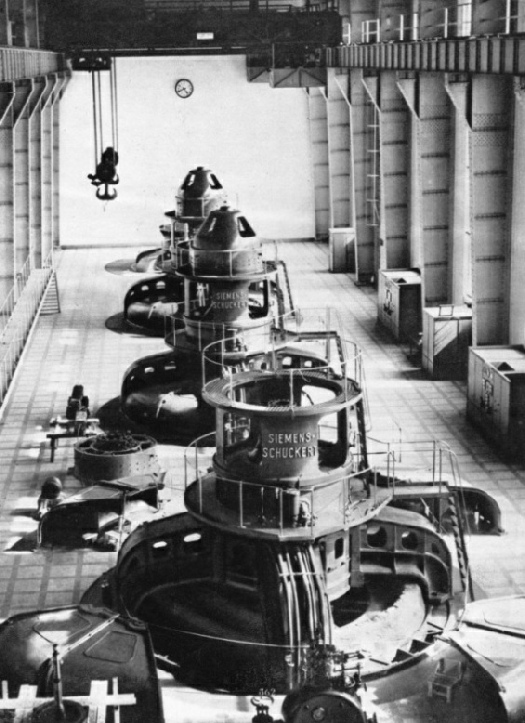

For more than four years thousands of engineers and labourers were engaged on the building of an enormous power scheme by which the waters of the River Shannon, in the Irish Free State, have been harnessed to drive massive turbines. Above the well-known city of Limerick, water from the Shannon has been diverted by a huge weir into a headrace or large canal which is seven and a half miles long. At Ardnacrusha the headrace is dammed by the intake building, in which is incorporated a navigational lock. Through enormous pipes known as penstocks the water flows, with a head of 100 feet, to the turbines. Having passed through the power-house, the water is returned to the Shannon through a tailrace which is more than a mile long. This chapter is the third article in the series on Wonders of Water Power.

The Shannon Power Scheme (photogravure supplement)

The Shannon Power Scheme:

Photogravure Supplement

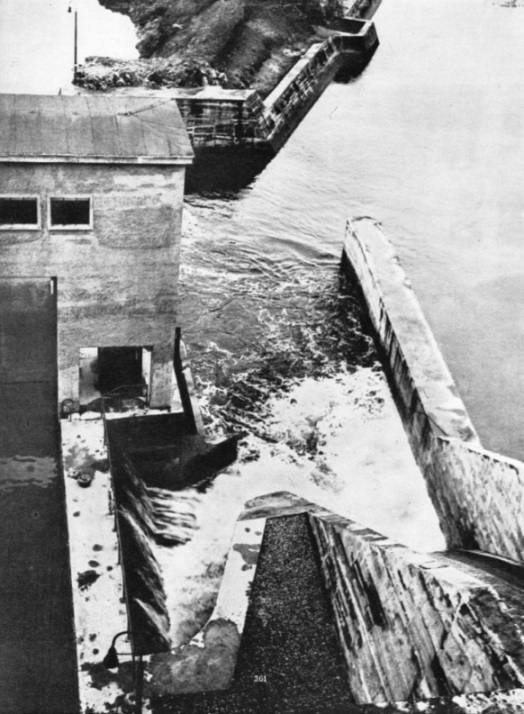

A SPILLWAY CHANNEL alongside the navigational locks at Ardnacrusha is designed to take an emergency flow of water from the headrace. Thus when a turbine is shut down a valve opens the spillway sluice and the release of water compensates for the sudden stoppage of the flow through the penstocks. On the left is the special sluice which empties the water from the lock into the tailrace.

Contents of Part 12 (continued)

How Air is Conditioned

By having made it possible to control the temperature and humidity of air supplied to factories, houses and transport vehicles, the engineer has added materially to the efficiency of many industries, and also to personal comfort. The science of air conditioning is receiving a great deal of attention nowadays. It has considerable influence not only on health and comfort, but also on industrial conditions. The various systems which engineers can now install in buildings, ships, factories and so on are described in this chapter.

LNER Streamlined Locomotive

Four world’s records in steam traction were claimed in 1935 for a London and North Eastern Railway Pacific locomotive of the A4 class. Engines of this class are streamlined developments of the well-known high-pressure 4-6-2s of the A3 class, designed by Sir Nigel Gresley.

No. 4482, Golden Eagle, illustrated below, is one of a class of seventeen A4 Pacifics built in 1936-7 to haul the fastest expresses on the LNER. This is the fifth article in the series on Modern Engineering Practice.

The Modern Coal Mine (Part 1)

Continual experiment and research are being carried out by engineers to find new methods of mining for coal and to minimize the many dangers which miners incur in their work underground. Coal mining is one of the most important of engineering subjects, one in which the human element is a big factor. This chapter describes the marvellous improvements which are now used to aid the miner in his work and to minimize the danger in which he toils. This chapter describes also machines such as the automatic cutters which are replacing where possible the more laborious method of hand cutting from the coal face. The article is concluded in part 13.