© Wonders of World Engineering 2014-

Part 14

Part 14 of Wonders of World Engineering was published on Tuesday 1st June 1937, price 7d.

Part 14 includes a photogravure supplement showing the Victoria Falls Bridge, which illustrated the article on this project.

The Cover

The cover this week shows an intake gantry at the works on the Bonneville Dam, Tennessee, USA. The dam is part of a huge project designed fro navigational purposes, for the control of floods and for the harnessing of water for a hydro-electric power scheme.

Contents of Part 14

Fighting the Drought Menace (Part 2)

A chapter dealing with many of the irrigation schemes in Australia, and describing the building of the huge Burrinjuck Dam in New South Wales. The article is concluded from part 13. It is the fifth part in the series on Triumphs of Irrigation.

High-Pressure Locomotive

At first sight the locomotive illustrated below does not, judged by modern standards, look anything out of the ordinary, but it is, nevertheless, an interesting and unique engine. The running parts are, in the main, those of a 4-6-0 express locomotive of the German

State Railways, but there are three cylinders and three distinct boilers. All the boilers work at different pressures. The locomotive is an experimental one, built for the Schmidt’sche Heissdampf Gesellschaft, by Henschel und Sohn, Cassel, Germany.

Electric Power from Steam

One of the largest power stations in the world, in which electricity is produced by steam turbines, has been built on land reclaimed from the waters of Lake Michigan, North America. This chapter describes how electricity is produced from coal at the huge State Line Power Station at Chicago. This great steam-driven power house has been planned to have a capacity of 1,000,000 kilowatts.

The Victoria Falls Bridge

An outstanding feature of the Cape to Cairo route is the great bridge which spans the gorge of the Zambezi River below the Victoria Falls in the heart of Africa. The bridge was built in Great Britain and assembled at the site. Not far from the Victoria Falls, discovered by Livingstone in 1855, the Zambezi River flows through a deep gorge and across this gorge a slender single-span steel arch now carries a railway. The bridges itself is of outstanding interest and the way in which it was thrown across a deep gorge, miles from civilization, is described in this chapter. This is the fourth article in the series Linking the World’s Highways.

The Victoria Falls Bridge (photogravure supplement)

The Victoria Falls Bridge:

Photogravure Supplement

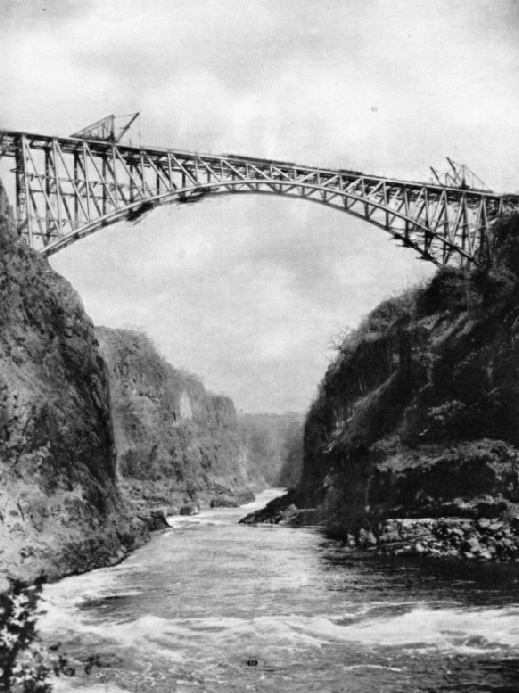

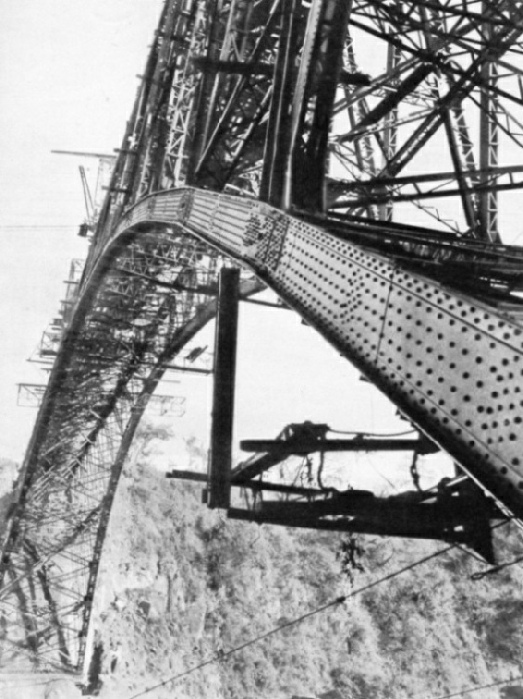

THE CENTRAL ARCHED SPAN of the Victoria Falls Bridge measures 500 feet. It is flanked by two straight spans of braced girders, that on the north bank being 62 ft 6 in long and that on the south bank 87 ft 6 in long. The arch is formed by two arcs side by side and inclined inwards. The main girders are 27 ft 6 in apart at the upper ends and 53 ft 9 in apart at the abutments.

Contents of Part 14 (continued)

Conquest of the Rockies

The building of the Canadian Pacific Railway across the muskeg swamps and prairies, over the foothills, and through the forbidding range of the Rocky Mountains was one of the finest epics of the pioneers of engineering. In this chapter the story of the Canadian Pacific Railway is told, describing the expeditions which carried out the preliminary surveys and finally selected the most practicable route by which the railway could be carried from eastern Canada to the shores of the Pacific. No detailed maps existed. The surveyors had to fight their way through dense forests and across mountain ranges where few white men had ever ventured before. Twelve thousand men were chosen to build this great railway through swamps, vast prairies and mountains. To add to the difficulty of surmounting almost incredible natural obstacles, there were all the rigours of Arctic blizzards, and the dangers of attack from Indians and wild beasts. This is the fourth article in the series on Railway Engineers at Work.

William Murdock

Son of a Scottish farmer millwright, William Murdock proved his worth and versatility during his long association with the firm of Boulton and Watt. Murdock is chiefly remembered for his invention of coal gas lighting. This is the sixth article in the series on Makers of Engineering History.

Tunnelling the Hudson (Part 1)

For thirty years obstacles baffled and tragedy thwarted all attempts to complete a tunnel beneath the Hudson River, New York, but at length the engineers achieved a lasting victory over the forces of Nature. This is one of the most amazing stories of engineering. The Hudson Tunnel was begun in 1874, but thirty years of frustration, tinged with tragedy, were to elapse before it was completed. The article is concluded in part 15, and is the third article in the series Below the Surface.

The Victoria Falls Bridge:

Photogravure Supplement 2

THE FINAL STAGES. The centre panels of the arch were completed on March 31, 1905. The ends overlapped by only 1¼ in, but when the engineers came to complete the work next day they found that contraction during the night had caused the ends to meet with precision.

The Victoria Falls Bridge:

Photogravure Supplement 3

1,500 TONS OF STEELWORK were used in the Victoria Falls Bridge. The bridge was built at Darlington, Co. Durham, and assembled there in sections to ensure that every component was perfect. Then the sections were conveyed to the heart of Africa by sea and by rail. At one time there were 400 natives working on the bridge.