© Wonders of World Engineering 2014-

Part 27

Part 27 of Wonders of World Engineering was published on Tuesday 31st August 1937, price 7d.

Part 27 includes a colour plate showing a powerful electric lifting magnet at work. It formed part of the article on Electric Lifting Magnets. The colour plate was also used as the cover design for this part. It also formed the frontispiece to Volume 2.

The Cover

This week our cover shows a powerful electric lifting magnet at work in a scrap yard, moving empty shell cases. The lifting magnet is attached to a 5-tons overhead travelling crane. The magnet is circular, a type suitable for lifting such loads as pig iron, solid ingots and scrap metal.

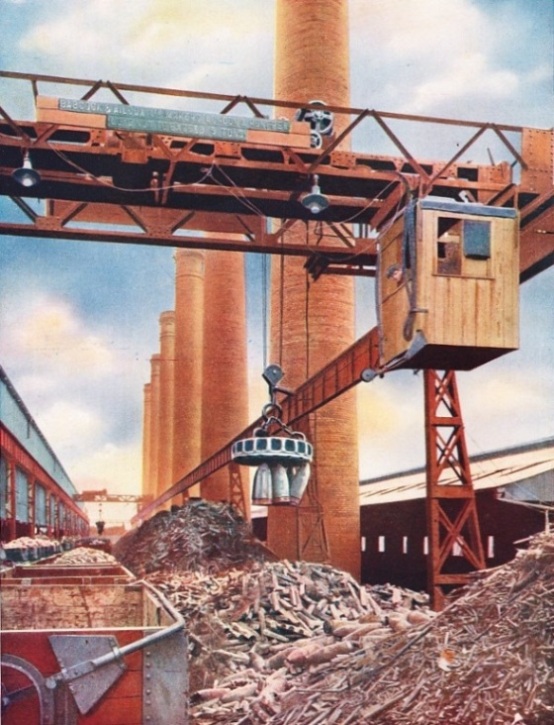

Powerful Electric Lifting Magnet

POWERFUL ELECTRIC LIFTING MAGNET at work in a scrap yard, moving empty shells and other pieces of scrap metal. The magnet, which is of the circular type, is attached to a 5-tons overhead travelling crane. Lifting magnets of circular shape are most suitable for such loads as pig iron, solid ingots and scrap metal of varying sizes. Direct, or continuous current is used for electric lifting magnets, and they are generally built for a 110-volts or 200-volts supply.

Contents of Part 27 (continued)

Electric Lifting Magnets

One of the most spectacular applications of the principle of electro-magnetism is the use for industrial purposes of giant electric magnets capable of lifting loads of up to 25 tons in weight.

Europe’s Highest Telephone Exchange