© Wonders of World Engineering 2014-

Part 34

Part 34 of Wonders of World Engineering was published on Tuesday 19th October 1937, price 7d.

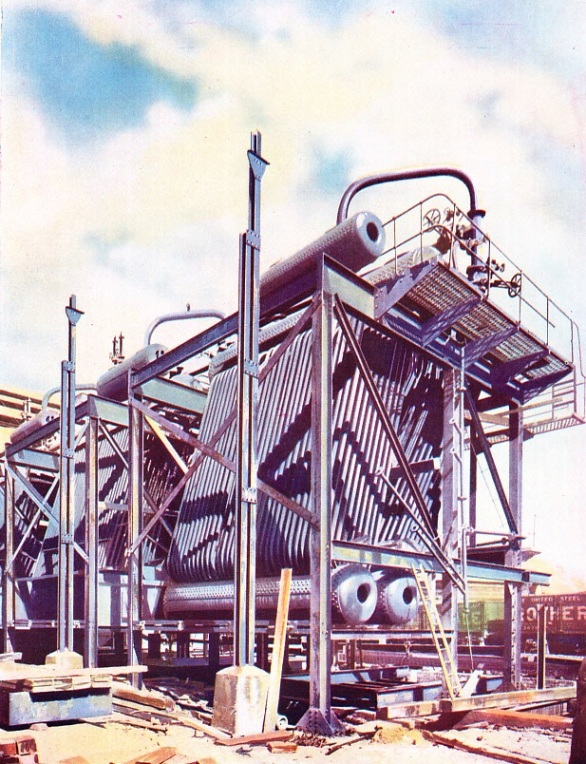

Part 34 includes a colour plate showing a large water tube boiler at Orgreave Colliery, near Sheffield. It formed part of the article on Testing boiler installations, and was also reproduced on the cover.

The Cover

This week’s cover, which is reproduced as a colour plate, is published by courtesy of John Thompson & Co Ltd. It shows a large water tube boiler in course of erection at a colliery. The principle of the water tube boiler is described in a previous chapter, and the methods of boiler testing are described in the chapter which appears in this week’s Part.

Contents of Part 34

Canada’s Mineral Wealth (Part 2)

A chapter describing how the most advanced types of mining equipment has enabled Canada’s output of metal to multiply tenfold since the beginning of this century. This article is concluded from part 33.

Large Water Tube Boiler (colour plate)

Contents of Part 34 (continued)

Testing Boiler Installations

The efficiency of a boiler is a matter of paramount importance. Extensive test are made to find out if an installation is working at maximum efficiency, the amounts of steam generation and of fuel consumption being carefully recorded. Steam engineering is a wide subject, and one of tremendous importance. We have already had a chapter on the development of the boiler, and this chapter is on the testing of a boiler installation. Several tests have to be made. The engineer wants to know how much steam the boiler will evaporate for every pound of coal burned; what pressure the boiler will stand; whether it is capable of maintaining the pressures demanded at “peak load” periods; and so forth. The methods of carrying out these and many other tests are briefly described in this chapter.

Flights in the Stratosphere

The altitude record for aeroplanes was raised in 1937 to more than 50,000 feet, at which height continued research is being carried out by the Royal Air Force to explore the possibility of establishing regular military and commercial flights in the upper atmosphere. This chapter describes the systematic study of the problems involved by flying at great altitudes - in the region known as the stratosphere. The object of balloon ascents, however, is mainly scientific, and much material relating to the physical properties of the upper atmosphere has been collected. In more recent years several high-altitude flights have been made by aeroplanes, and the Royal Air Force has been making a detailed study of high-altitude flying from the military and commercial points of view. This chapter describes some of the problems encountered by the Royal Air Force in its high-altitude research work.

You can read about Professor Piccard’s ascent into the stratosphere in Wonders of World Aviation.

Dredgers at Work

The great harbours and navigable rivers of the world would soon become silted up were it not for the incessant work of the dredger. Various types of dredgers, too, are used for the building of seaports and for the excavation of the world’s great canals. This chapter describes some of the more important types of dredger and some of the amazing feats which have been accomplished by them.

If you are interested in reading more about dredgers, there is a chapter on Dredgers and Hoppers, and on a Non-Self-Propelling Bow Well Bucket Dredger in Shipping Wonders of the World.

Sweden’s Hydro-Electric Schemes (Part 1)

The rivers of Sweden are inexhaustible sources of power which could be obtained otherwise only from imported fuel. The vast network of hydro-electric stations supplies electricity for the railways, industries and mines of the country. Until recent years the whole of Sweden’s railway system was dependent upon imported coal. With the advance of electrical engineering during the present century, however, Swedish engineers have found that their country has many compensations for its lack of coal, and they have developed “white coal” - water power. In this chapter are described some of the great modern generating stations of Sweden.

The article is concluded in part 35 and is the fourth article in the series Wonders of Water Power.