© Wonders of World Engineering 2014-

Part 37

Part 37 of Wonders of World Engineering was published on Tuesday 9th November 1937, price 7d.

Part 37 includes a photogravure supplement showing some of the dams built by the US Reclamations Bureau. This section illustrates the article on Desert Reclamation in the West.

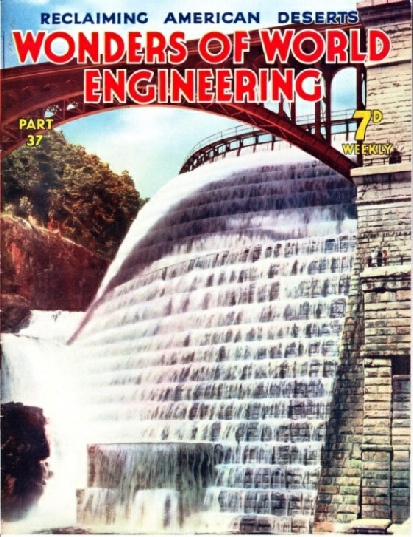

The Cover

The cover this week shows the spillway section of the dam of the Croton Reservoir, near New York. This reservoir stores the water of the Croton River which, before the dam was built in 1906, flowed into the Hudson River. Water from the reservoir is conveyed to New York City by an aqueduct about thirty-three miles long, with a capacity of 300,000,000 gallons a day. In Great Britain and in many other countries, when a dam is built across a river, provision is generally made to allow a certain proportion of the water to flow down the bed of the dammed stream. This is known as compensation water. In this instance, however, no compensation water is needed and the Water Department of New York City has planned to draw off the water which flows down the spillway of the Croton Dam. An additional aqueduct is being built to take this extra supply of water to New York City. When this is completed the only water which will flow down the spillway will be flood water.

Contents of Part 37

Story of Tyre Production (Part 2)

This chapter describes the manufacture of pneumatic tyres. The article is concluded from

part 36 and is the twelfth article in the series on the Romance of Industry.

The Uses of Compressed Air

Apart from its use in motor ships and on railways, compressed air is an excellent source of power for rock drills, riveting hammers and other engineering implements. It is easily produced and distributed, and is perfectly safe in mines or other dangerous situations. Various forms of power and power transmission are available to the modern engineer. Steam, electricity and hydraulic power immediately come to mind, but there is another source of power - compressed air - which often escapes attention in spite of its common applications.

The principles and numerous applications of compressed air are described in this this chapter.

Reclamations Bureau of the United States

More than one hundred dams have been built by the Reclamations Bureau of the United States Government in the Western States. These structures have irrigated and made productive millions of acres of barren waste. This chapter descrbes the large-scale engineering works which the Federal Government of the United States is sponsoring in the Western States. The Federal Government is conducting great engineering enterprises in all parts of the United States, including the work of the Tennessee Valley Authority, which was described in an earlier chapter. This is the eighth article in the series Triumphs of Irrigation.

Desert Reclamation in the West (photogravure supplement)

Reclamations Bureau of the United States

Photogravure Supplement - 2

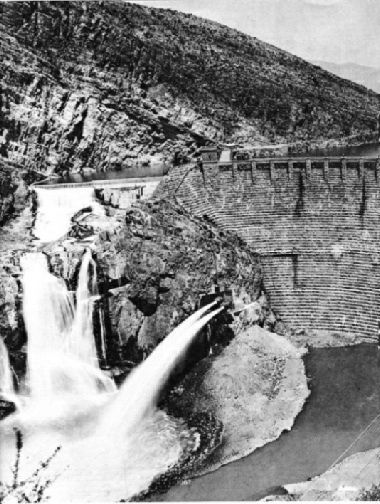

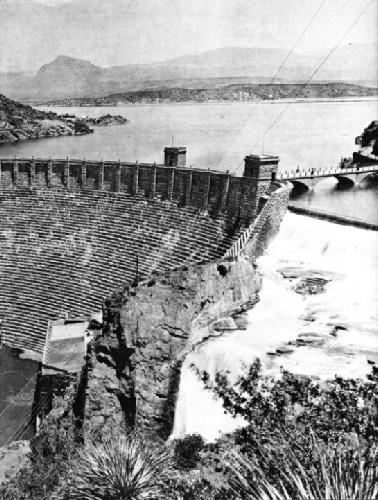

TWO SPILLWAYS, one on either side of the dam, release the overflow waters from the reservoir created by the Roosevelt Dam, across the Salt River, Arizona. The spillways have a normal capacity of 113,000 feet a second, and are each 200 feet long. The dam is of rubble masonry with coursed rubble faces, laid in Portland cement mortar. It has a length of 1,125 feet at the crest and a width of 158 feet at the base, with a height of 280 feet.

Reclamations Bureau of the United States

Photogravure Supplement

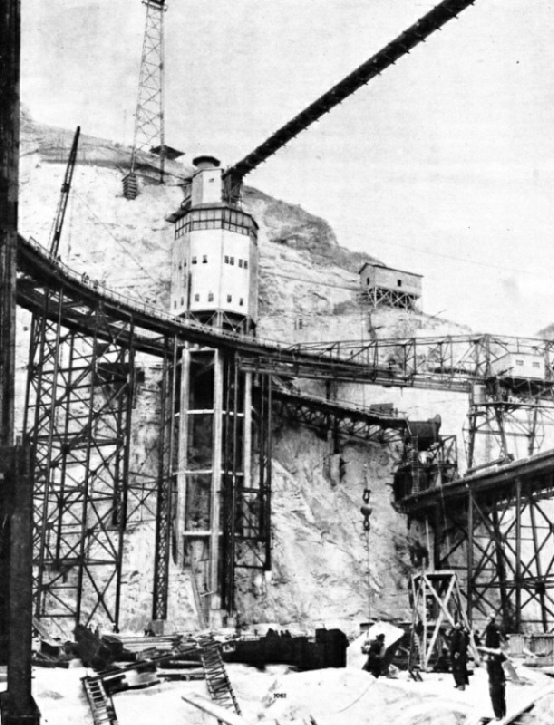

CONCRETE MIXING PLANT on the site of the Grand Coulee Dam, ninety-two miles west of Spokane, in the State of Washington. The first pouring of concrete was made in December 1935, and pouring was continued at an average rate of 5,714 cubic yards a day. The dm is by far the greatest of all concrete structures. It is designed to raise the upstream level of the Columbia River by 355 feet, thus creating a reservoir with a surface area of 128 square miles.

Reclamations Bureau of the United States

Photogravure Supplement - 3

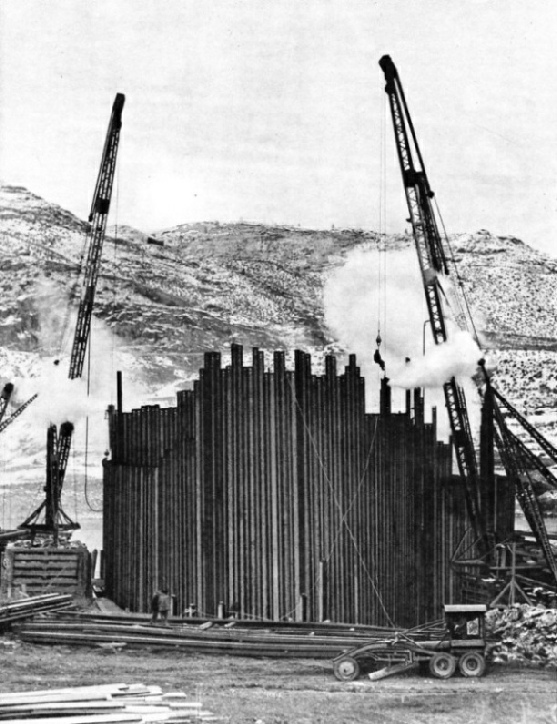

GIANT COFFERDAM of sheet steel piling being built to divert the Columbia River and allow work to proceed on the foundations of the Grand Coulee Dam, Washington. Three cofferdams in all were built, having a height of 125 feet and a total length of about 5,000 feet. The Grand Coulee dam is designed to reclaim more than one million acres of virtually desert land and to provide for the generation of electrical energy amounting to 2,700,000 horse-power.