The skyscrapers of New York and other American cities rise to heights of 500 feet or more above the level of the streets. These giant buildings have been evolved with the object of solving modern problems of congestion

NO ocean voyager, however wide his experience, ever forgets his first sight of New York from the sea. As the skyscrapers come over the horizon, he obtains a glimpse of fairyland - something totally fantastic and unreal. On a closer approach, New York might be some toy town built by giant children with a mammoth box of bricks. Closer still, the mind is bewildered by the attempt to grasp the real size of these gigantic, slender towers, even the smallest of them housing the population of a reasonably-sized town.

NO ocean voyager, however wide his experience, ever forgets his first sight of New York from the sea. As the skyscrapers come over the horizon, he obtains a glimpse of fairyland - something totally fantastic and unreal. On a closer approach, New York might be some toy town built by giant children with a mammoth box of bricks. Closer still, the mind is bewildered by the attempt to grasp the real size of these gigantic, slender towers, even the smallest of them housing the population of a reasonably-sized town.

Except for the Eiffel Tower, Paris - a mere skeleton of iron - there is nothing in the Old World with which to compare them. The summit of the Great Pyramid is less than 500 feet above the desert; in New York there are numerous skyscrapers, crowded together at the end of a small island. Forty of these buildings exceed 500 feet in height and two of them are over 1,000 feet high. Some - particularly the tallest and most recent - are graceful in outline; but, one and all, it is their immense height which stuns and bewilders the spectator. They seem to have stood for ages and to have been planned for eternity.

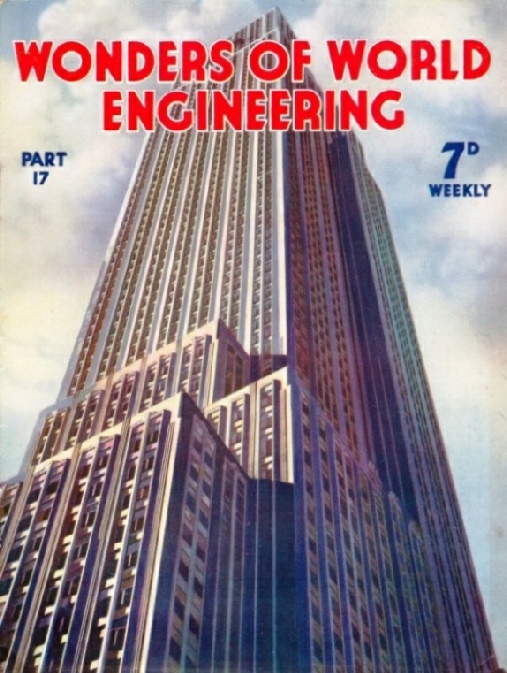

FIFTH AVENUE, one of the main thoroughfares of New York, appears almost to be a trench, so dwarfed is it by the huge buildings. The Empire State Building, dominating the scene, towers to a height of 1,250 feet. It is built on the site of the old Waldorf-Astoria Hotel, at the corner of Fifth Avenue and 34th Street.

Their history, however, goes back little more than fifty years. The first skyscraper was built in 1884 and was demolished in 1931 to make room for a much larger building. Such, too, has been the fate of many of its successors, mere dwarfs of 400 feet or so, but yet topping the cross on the lofty dome of St. Paul’s Cathedral. It is hard for the Londoner to imagine St. Paul’s lying in a deep man-made canyon, but that is what would have happened had the skyscraper found a home on Ludgate Hill or in Cheapside.

The skyscraper is an American product. But the construction of these huge buildings has not been brought about by mere megalomania or by the desire to go one better than the next man. They represent the simplest and the most logical solution of the problem of economizing space in the heart of great commercial cities. Nowhere in the world has that problem pressed more insistently for solution than in New York proper, with a huge daytime population and a small, seagirt territory incapable of lateral expansion. That is why New York is the home, though not the original home, of the skyscraper.

The first skyscraper was erected in Chicago, and for some time that city enjoyed a monopoly of them. This is sufficiently indicated by the earliest extant definition of the word “skyscraper” - a term which came into use several years later than the building defined. A dictionary published in 1891 defined a skyscraper as “a very tall building, such as are now being built in Chicago”.

The basic principle on which all skyscrapers from first to last have been designed is not American at all. It was first enunciated by a French architect, Eugene Viollet-le-Duc (1814-79), although he made no attempt to put it into practice.

No doubt the idea of a metal-framed building struck his contemporaries - accustomed to provide for the structural strength of their buildings by ponderous masonry, and by that alone - as simply fantastic. Yet it was perfectly sound; and, if buildings were ever to rise more than a certain height above ground level, its adoption was not only natural but also inevitable.

There are two well defined limits to the height of any building - the total weight which its foundations will support, and the load which the materials composing it will endure without being crushed. These limits operate severely in a tall masonry building. For the lower stories to support the dead weight of the upper without crushing, they must be thick. Thus a height is soon reached beyond which the total weight of the whole building will be too much for the foundations. In addition, the thick walls most seriously restrict the available accommodation space in the lower stories, and even on a foundation of living rock, eliminating all space for accommodation, it would be impossible to go on building upwards indefinitely. A height would soon be reached at which the weight of the upper stories would crush the stone of the ground-level portion, even if this were solid.

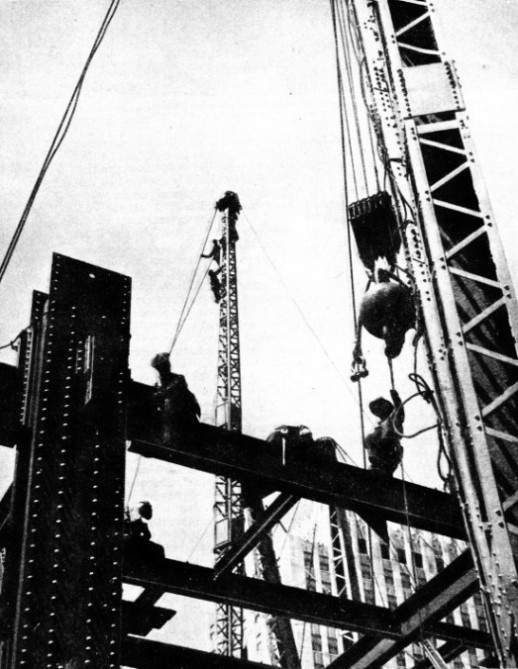

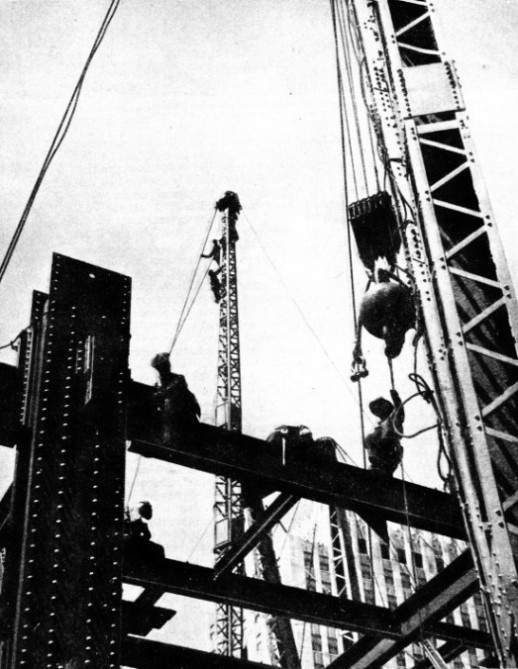

ON THE TWENTY-FIFTH FLOOR of the Federal Building, New York, workmen swing in a load of granite from a crane. In building skyscrapers the steel frame is first completed to its full height. Then the floors and walls are built round the towering skeleton of steel.

For example, the tallest masonry building ever erected for commercial purposes, the Monadnock Building at Chicago, was only sixteen stories high. To reach this height the basement walls had to be made no less than 15 feet thick. The tallest structure of stone ever raised by man, the Washington Monument (Washington, D.C.), a built-up, almost solid stone obelisk, is no more than 555 feet from the ground level to the aluminium cap which surmounts it. This is not far from the limit of height which it is possible to reach with masonry, and it was attained only by keeping the interior solid, except for a narrow internal stairway leading to the observation gallery. Yet a skyscraper has since been built which exactly copies the Washington Monument in height and outline, affording at the same time enormous internal accommodation. Furthermore, the Empire State Building is more than twice as high, and there seems to be no engineering difficulty, with present-day methods, in the way of erecting a steel-framed building 3,000 feet high or even more.

The building of skyscrapers, then, and of large numbers of modern buildings all over the world, is not so much a matter of architecture as of engineering. The engineer is the maker of the modem giant hotel, the mammoth cinema, the vast block of flats; and he goes about the job as if he were building a bridge or a battleship. He designs and builds a huge frame of steel, immensely stronger and more efficient than any structure of brick or stone could ever be. An alternative, reinforced concrete, is used in many instances, but so far no reinforced concrete building has reached, or seems likely ever to reach, the dimensions of many of the American giants.

The First Skyscraper

In 1880 a young architect of Minneapolis, named L. S. Buffington, came across Viollet-le-Duc’s suggestion, and began to turn it over in his mind. He visualized iron-framed structures of twenty-five or thirty stories, twice as high as anything then standing. At odd moments he would sketch them in outline, map out their building details, and even calculate the quantities of material required. He devised a name for them, too - he called them “cloud-scrapers”.

Buffington’s “cloud-scrapers”, however, remained on his drawing board, and his attempts to convince others that they were practicable caused him only to be regarded as a man whom it would not be safe to trust with a big commission - a visionary, or at best a harmless crank. He did ultimately - in 1887-88 - patent his system of constructing such buildings; but although he brought several suits for infringement he never won any, for an excellent reason: another man had already put Viollet-le-Duc’s suggestion into practice.

Buffington’s “cloud-scrapers”, however, remained on his drawing board, and his attempts to convince others that they were practicable caused him only to be regarded as a man whom it would not be safe to trust with a big commission - a visionary, or at best a harmless crank. He did ultimately - in 1887-88 - patent his system of constructing such buildings; but although he brought several suits for infringement he never won any, for an excellent reason: another man had already put Viollet-le-Duc’s suggestion into practice.

FOUNDATIONS for the Rockefeller Center, a group of buildings occupying an area of 12 acres between 48th and 51st Streets and between Fifth and Sixth Avenues, New York. Excavation on the site was started in July 1931, building began at various points between September 1931 and September 1934, and the greater part of the scheme had been completed by May 1935.

He was William Le Baron Jenney, a Chicago architect. He hailed from New Bedford (Mass.) and had studied architecture in Paris. In 1884 he designed the ten-storied Home Insurance Building, the first on record which relied for its structural strength upon a complete skeleton frame of iron, erected independently and afterwards enclosed in masonry. Jenney’s specification originally called for wrought-iron beams throughout; but while the building was still in progress the contractors, the Carnegie-Phipps Co., of Pittsburgh, Pa., sought and obtained permission to replace the wrought iron with Bessemer steel in the four uppermost stories. Many of the early skyscrapers embodied a large proportion of cast iron, which, so long as it is in compression only (for pillars, for example), is a suitable material.

This practice was discontinued after the collapse of the thirteen-storied Darlington Apartment House, New York, on March 10, 1904. It was never established that the cast-iron work freely used in this building had anything to do with the disaster, but cast-iron was never used in a skyscraper again. Jenney’s Home Insurance Building supported, with complete equanimity, the addition of two extra stories in 1890. It stood until 1931, when it was demolished as obsolete. Its demolition roused considerable interest in architectural circles. Its claim to be the first iron-framed building had been hotly disputed. Its designer was dead, the plans had disappeared and the only evidence on the subject - the iron frame itself, if it existed - had been hitherto concealed behind the masonry. Jenney’s surviving partner, W. B. Mundie, championed his rights most vigorously, and photographs taken at different stages of the demolition put the existence of the iron frame beyond all dispute.

Z-Section Columns

In 1887 the Home Insurance Building was joined by a second Chicago skyscraper, the Tacoma Building. Here for the first time the outer masonry walls were purely ornamental - mere curtains hung on the steel frame. Jenney had used the walls of his building as auxiliary supports. This was a step in advance, and it might be thought that the next step would be to discard the masonry altogether. Although it would be perfectly practicable, from the engineering aspect, to erect a skyscraper in which masonry was entirely eliminated, this has not yet been done on a large scale. An all-steel structure, however thoroughly it may be painted, needs constant attention to preserve it from rust; for example, a “maintenance party” of scrapers and painters has been continuously employed on the Forth Bridge, year in and year out, since this was finished in 1890. By encasing such a structure in masonry, which weathers much better, this work is obviated.

Two years later another Chicago skyscraper, the Rand McNally Building, set a fashion in framework which all succeeding skyscrapers have followed. Its skeleton was composed of rolled-steel beams and columns, built up of standard bridge-steel shapes and riveted together. Such a framework can be made piecemeal, in different places if necessary, and assembled with complete certainty that all the parts will fit. A little later, Jenney designed his Leiter Building, the first without a single self-supporting wall, external or internal, and his Fair Building (1891) was the first to use Z-section columns.

SKELETONS OF STEEL for a huge block of flats in the slum area on the East Side of New York. In the background on the left is the Woolworth Building, 792 feet high, built in 1913. The completed structure in the centre is the Municipal Building.

The designers of the early Chicago skyscrapers found themselves considerably handicapped by the fact that it was no easy matter, in that city, to get a firm foundation for a tall building. Chicago floats on a bed of soft sand and mud, and its skyscrapers were supported upon what were, in effect, great rafts of reinforced concrete. Even with the most careful calculation and distribution of the load, it was impossible to ensure that such rafts would not tilt slightly. If this happened, the superimposed building would tilt as well.

The fact first attracted public attention more or less by accident. A Chicago newspaper man was calling on a friend who lived opposite one of the latest skyscrapers. His friend had tied a weight to the cord of his window blind - turning it, in effect, into a plumb line. The reporter happened to get one side of the giant building in line with the cord - and noticed that, instead

of being coincident, or parallel, they diverged considerably. There was no draught in the room. The cord was quite flexible and the weight heavy. The plumb line must be vertical, unless something had gone wrong with the law of gravitation. It followed, therefore, that the skyscraper must have tilted to one side. So it had, as careful measurement revealed, the maximum deviation from the vertical being about 9 in.

This, although perceptible, was not enough to matter seriously. The famous Leaning Tower of Pisa, which is 14 feet out of plumb, has stood for six centuries. The discovery of the deviation, however, led to provision being made, in later skyscrapers, for truing them bodily, by hydraulic jacks, should they tilt more than a fraction of an inch.

This 9-in. tilt was the largest ever encountered, but among the early Chicago buildings an occasional tilt of 3 in. or 4 in. was not uncommon. The first indication of tilt was the “chattering” of the elevators in their hoists.

Without the elevator the modern skyscraper would never have come in to being. No one can seriously visualize business men habitually doing what some of the unfortunate New Yorkers have to do during a strike of elevator attendants - climbing up thirty or forty flights of stairs every morning to reach their offices. The elevator antedated the skyscraper by twenty-five years, the first one being designed by Otis Tufts for the then new Fifth Avenue Hotel, New York City, in 1859.

to being. No one can seriously visualize business men habitually doing what some of the unfortunate New Yorkers have to do during a strike of elevator attendants - climbing up thirty or forty flights of stairs every morning to reach their offices. The elevator antedated the skyscraper by twenty-five years, the first one being designed by Otis Tufts for the then new Fifth Avenue Hotel, New York City, in 1859.

Only two elevators of this design were built. The centre of the lift shaft was occupied by a vertical shaft with a fine screw thread cut on it, and a nut built into the floor of the lift engaged with this thread. The shaft was rotated by steam power, and this screwed the lift up or down. Later came the hydraulic lift, and ultimately the high-speed electric elevators common in the United States to-day.

IRONWORKERS have extremely dangerous jobs perched on the steel frame of a skyscraper perhaps 1,000 feet above ground level. The cranes swing the huge beams and girders into position and the ironworkers fix all the steel framework into place.

As exemplified by those fitted in the Empire State Building, they are apt to give the neophyte the same uneasy feeling which one gets when tossed in a blanket. The expresses, “not stopping below the twentieth floor”, can be shot upwards at the rate of 1,000 feet a minute, and could, if required, be accelerated downwards more rapidly than gravity performs this, so that passengers in them would leave the floor and be overtaken by the ceiling.

The successful building of the first two Chicago skyscrapers directed the attention of New York architects to this form of construction. Not only was the need for economizing space much more pressing in New York, but also that city, being based upon rock, had a perfect foundation for skyscrapers.

The year 1889 saw the first New York skyscraper, the Tower Building on Broadway. This building was demolished in 1914. It was not much more than 200 feet high and gave little promise of the enormous structures which were to follow. A more notable building, however, took shape in 1893. This was the Manhattan Life Insurance Building, 344 feet high, with seventeen stories and a tower. For fifty-two years, the apex of New York had been the top of Trinity Church steeple (built in 1841) which stands 284 feet above Broadway. Now, for the first time, it had been overtopped.

Regulated Building

To-day Trinity Church, except from close by, is invisible - lost among its gigantic neighbours. The record set up by the Manhattan Life Insurance Building was repeatedly broken in succeeding years - notably by the Singer Building (612 feet high) in 1907 and a little later by the Metropolitan Life Building (658 feet high). Before the introduction of the New York zoning laws in 1916, the highest building in New York was the Woolworth Building of 1913 (792 feet high), second place going to the City Bank Farmer’s Trust Building, with a height of 745 feet.

Until 1916 the height of buildings in New York was not governed by any special regulations or ordinances. Some American cities - Washington, for example, and Boston - had followed the rule, common to most European capitals, of limiting the height of all new buildings to the width of the narrowest abutting street, as measured between the building lines on either side. But the New York architects were originally free to build as high as they pleased, a fact of which they took full advantage. Yet the laws of 1916, designed to restrict the activities of skyscraper builders, have caused the production of higher buildings than have ever been seen before.

Not only are the skyscrapers built after 1916 higher than their forerunners, but they are also much more graceful. Before the introduction of the zoning laws, a building of any height whatever might be of exactly the same section throughout. To get the maximum possible value for acreage, it often was built in this way and thus looked ugly.

Not only are the skyscrapers built after 1916 higher than their forerunners, but they are also much more graceful. Before the introduction of the zoning laws, a building of any height whatever might be of exactly the same section throughout. To get the maximum possible value for acreage, it often was built in this way and thus looked ugly.

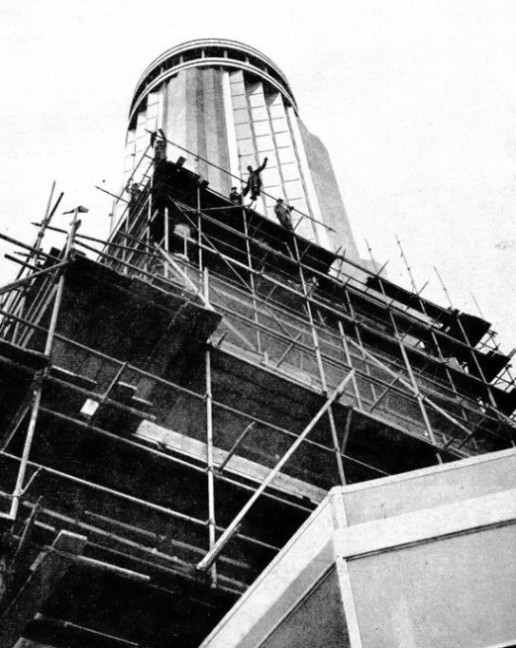

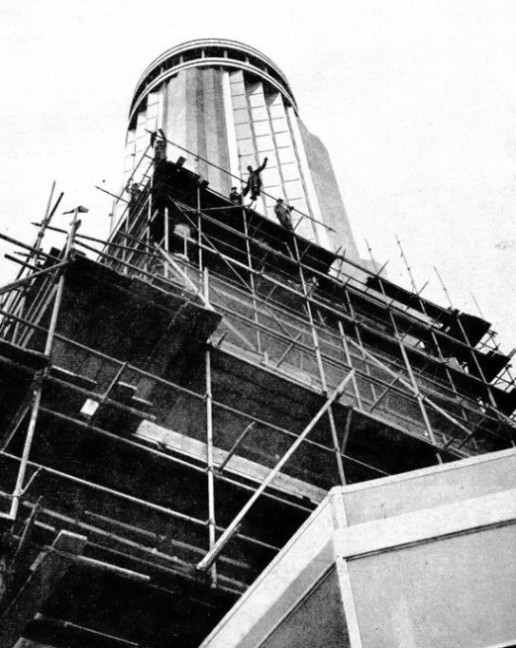

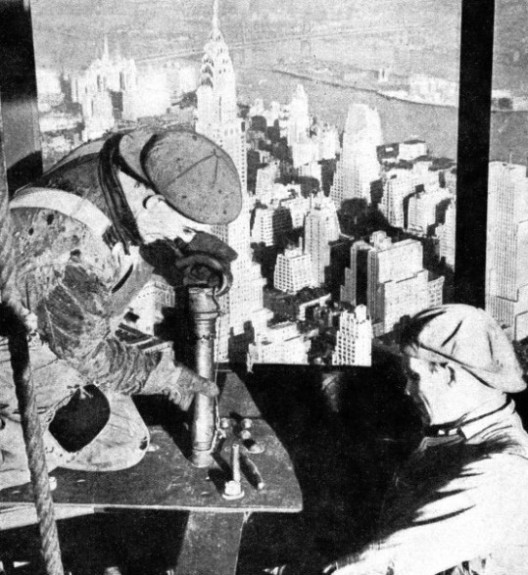

SCAFFOLDING at the top of the Empire State Building. The main tower of this structure is 1,045 feet high. Above this is the secondary tower, 205 feet high to the top of the airship mooring mast. Above this is a small mast equipped with anemometers and other instruments.

In 1916, however, New York passed the series of zoning laws governing the construction of future skyscrapers. Broadly speaking, these laws provide that, as to three-quarters of the area of any site on which a new building is erected, the edge of the building must, when it reaches a certain height, be stepped back a specified amount. This amount is governed by the width of the street on to which that edge of the building abuts. If the face of the building be carried up beyond the step, then at a second prescribed height it must be stepped back again, and so on. Over the remaining quarter of the site area, but no more, the building may be carried up vertically to any height desired.

New York skyscrapers dating after 1916, therefore, are bound to assume the form of a tapering base-building surmounted by a vertical tower. The details of the zoning laws are so complicated to understand and apply that a new profession has come into existence, that of the “consulting expert zoner”. The loophole for unrestricted vertical development left open by the “one-fourth area” clause has operated to increase the overall height of any structure to which the zoning laws apply. The 800-feet mark was soon passed. In rapid succession came, the Bank of Manhattan Building (838 feet), the Cities Service Co. Building (950 feet), the Chrysler Building (1,046 feet - the first to surpass the 984 feet of the Eiffel Tower) and, in 1930, the Empire State Building, 1,250 feet high overall - the loftiest structure yet built anywhere in the world.

Work on the Empire State Building began in October 1929. It was erected on the site of the old Waldorf-Astoria, for thirty-five years one of New York’s finest hotels. As a preliminary, therefore, that building had to be demolished with sledge hammers, compressed-air “jumpers”, and oxy-acetylene torches. The debris was removed in 16,000 truckloads. All the work of demolishing the old building and of erecting the colossal new one had to be performed in the heart of a crowded city, on a comparatively tiny plot of ground, and without causing any interruption to commerce or traffic.

But for the modern oxy-acetylene torch, it is doubtful whether the Waldorf-Astoria could have been demolished at all, except as a matter of urgent necessity - in which event it would have had to be dynamited, at enormous expense. Its heavy steel frame - heavier in gauge than those of more modern buildings - was riveted together, and the only practicable method of dealing with such a frame was to cut it apart. Done with ordinary cutting tools, the work would have taken years, at entirely prohibitive cost.

The oxy-acetylene torch, however, has solved such problems. Light and portable, it emits a flame whose temperature is about 6,300° Fahr. (an ordinary gas-stove flame is about 2,000°-2,700° Fahr.). Steel, melting at about 2,700° Fahr., gives way to this flame as though it were butter. Quarter-inch plates can be cut at the rate of 100 feet an hour and a speed of 17 feet an hour has been reached in cutting battleship armour plates 8 in. thick. The wreckers working on the Waldorf-Astoria went through the steel beams as if cutting timber with saws. Five months saw the demolition completed and the site - in the form of a hole in the ground - ready for its new occupant.

As in all modern New York skyscrapers, the foundations were dug out to bedrock. This process is generally estimated to entail removing an amount of earth and broken rock almost equal in weight to the building which takes its place - in this instance 303,000 tons. Since it is no longer the practice to set the lowest girders of the structure on the rock itself, 200 huge reinforced concrete cylinders, each 10 feet in diameter and capable of standing up to a load of 10,000,000 lb., were set in place, and over these went a steel “grillage”, distributing the weight of the building equally.

Excavated with Dynamite

These huge concrete pillars went down to bedrock, 30 feet to 40 feet below the basement level of the new building. While excavating the pits for them the engineers found themselves compelled to use dynamite. They managed to smother the “blasts” under enormous woven-steel mats, which allowed the gas of the explosion to disperse harmlessly, while confining the shattered rock fragments which would otherwise have bombarded the neighbourhood. Luckily, no springs or quicksands were struck during the sinking of the foundations. In that event airtight caissons would have had to be built, and the work carried on after the water had been driven back by compressed air - an expensive and laborious proceeding.

The work of erecting the steel framing of the huge building began in April 1930. The amount of steel used would have provided a complete double railway line between London and Manchester.

The work of erecting the steel framing of the huge building began in April 1930. The amount of steel used would have provided a complete double railway line between London and Manchester.

The first outward indication that the foundations were ready was the arrival and prompt erection of various giant steel derricks, electrically operated and controlled by a web of steel cables. Without these derricks, the material could never have been got into place by any amount of labour. With them at work, columns and beams were put together at an amazing pace. The columns and beams had been sent, all ready drilled, from many different firms scattered over the United States. As the frame rose the derricks rose with it.

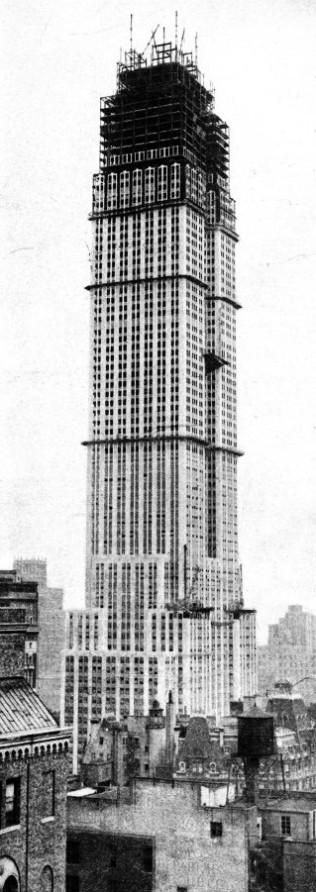

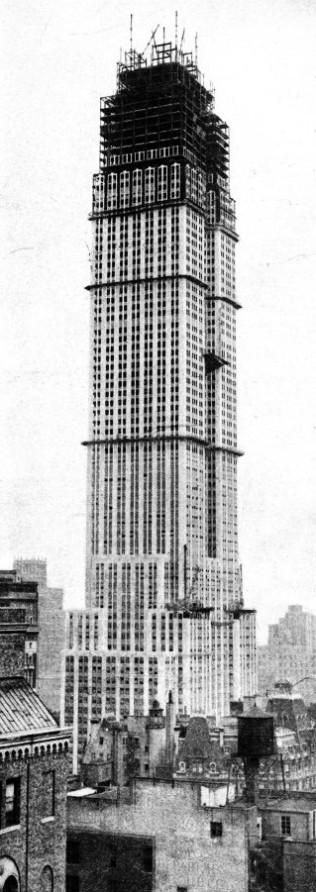

THE EMPIRE STATE BUILDING in course of construction. On April 7, 1930, the first of the steel columns of the frame was set up. By the middle of October the frame was complete and 60,000 tons of steel had been used. On May 1, 1931, the building was opened. There are eighty-six stories in the main tower. The steelwork went up at an average rate of four and a half stories a week, and the stonework at the faster rate of about one story a day.

The framing had to be planted on a comparatively small base. The total area available was only two acres, to three-quarters of which the provisions of the zoning laws applied. Here the building was to be only five stories high, but on the “unrestricted” portion (half an acre in area) would rise the main 86-storied tower, 1,045 feet high, and above that again the secondary tower, 205 feet high. The work had to be done in the heart of a crowded city. Every piece of material used came to the site in an ordinary motor lorry. Yet the skeleton went up with amazing speed, at the rate of four and a half stories a week; and the stonework followed it, when necessary, even faster - one story a day. In twenty-five weeks 57,000 tons of steel had been put into place, and the work was twelve days ahead of schedule. The Empire State Building was completed in just under one year.

The contractors (Starrett Brothers and Eken) employed a staff of about one hundred foremen and from 2,500 to 4,000 workmen. Pride of place must go to the “ironworkers”, that band of steeplejacks who are always to the fore when any big iron structure is going up, and who spend their usually short lives in cheerfully accepting, as part of the day’s work, the most appalling risks.

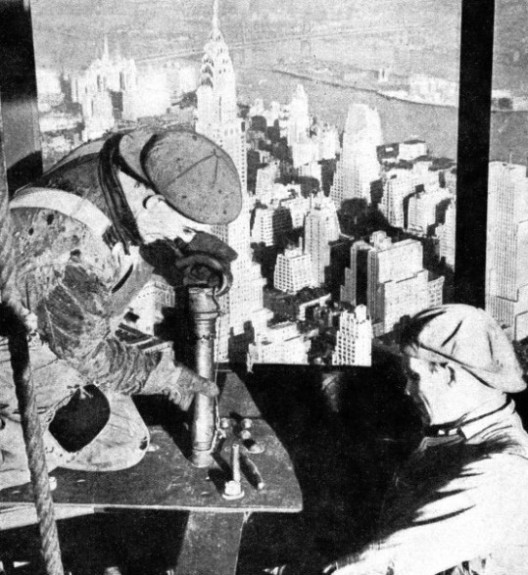

The ironworker is the pioneer, and without him a skyscraper could never take shape. Whenever a big beam goes into place, swinging between heaven and earth hundreds of feet from the ground at the end of a wire cable, you will find some ironworkers hanging on to a bare framing at the beam’s destination, ready to guide it into place and bolt it roughly down. Often one or two of them will be cheerfully “taking passage” on the beam itself. Since the disappearance of most of the full-rigged ships from the Seven Seas there has been no job quite the same as this. In the last century, the deep-water sailor-man was accustomed to find himself lying out on the yardarm in a gale of wind, all but flung from his perch at every roll and heave of the ship, holding on for dear life with one hand and doing his best to take in a reef with the other; but the ironworker of to-day has, if anything, the harder task.

He may be 1,000 feet up instead of a hundred or so. He has no footrope on which to put his weight, and no rigging to grab if he loses hold. He must guide and handle weights compared with which a ship’s mainyard is a toothpick. And yet, wherever there is work of this kind to be done, there you will find ironworkers in large numbers. Statistics available for the last twenty years indicate an average number of 15,000 ironworkers employed in the United States. During that period there have been some 2,000 fatal accidents. The proportion of serious, but not fatal accidents is much larger. Although the work is available all the year round, no ironworker is known to have had more than 207 days’ work in a full year. The ironworkers who ran up the frame of the Empire State Building were a typically mixed assembly. Americans, mostly from the Southern States, predominated. Then there were Irishmen, French-Canadians, half-breed Indians and Scandinavians.

10,000 Tons of Steel a Month

All possible safety devices were supplied and used, but the very nature of the ironworker’s job is such that it can never be made particularly safe. All possible pains were taken to protect the public. A wooden “catch-all” was built all round the building a few floors below the mason’s scaffolding, and backed up by one of wire some stories lower still. All exposed floors were surrounded with rope nets to stop material from being blown off them during strong winds. To safeguard against fire, and also to supply the workmen’s needs, a temporary water service was installed at the start, conveying water to the highest point and rising steadily with it. In all, the water system comprised about ten miles of piping.

The speed at which the ironworkers ran the main frame together can be judged by comparison of a few dates. On April 7, 1930, the first of the steel columns were set upright in place. These were one story in height and rose out of the concrete and steel “footing”, 35 feet below ground level, set into the rock of Manhattan Island. By the middle of April all the 200 columns had been built up as far as the second floor, and the construction was well under way, material going in at the rate of 10,000 tons of steel a month.

The speed at which the ironworkers ran the main frame together can be judged by comparison of a few dates. On April 7, 1930, the first of the steel columns were set upright in place. These were one story in height and rose out of the concrete and steel “footing”, 35 feet below ground level, set into the rock of Manhattan Island. By the middle of April all the 200 columns had been built up as far as the second floor, and the construction was well under way, material going in at the rate of 10,000 tons of steel a month.

RIVETERS in a perilous position at the top of the Empire State Building. In the background is the Chrysler Building, 1,046 feet high. This was the first structure to exceed the height of the Eiffel Tower, Paris.

Early in May the derricks had been planted on the eighth floor; by the middle of June they were on the twentieth, and the top of the frame was two stories farther up still, rising more rapidly than ever and swarming with half-naked workers. By mid-July, three-quarters of the steelwork was in place and the derricks were standing on the fortieth floor. Finally, by the middle of October, six months from the start, the steel frame stood complete. It weighed some 60,000 tons and rose more than 1,200 feet from the ground.

After the ironworkers followed the plumbers - not, in this instance, the traditional purveyors of wiped joints, but a gang of expert erectors whose job was to take over the framing as the ironworkers had left it, test it for truth, adjust it until it was plumb, true and square, and replace the ironworkers’ temporary bolts with permanent rivets. It seems likely, however, that in the near future welding, which is a probably stronger, more durable and certainly cheaper process, will take the place of riveting.

Following the plumbers upwards as the huge building rose into shape came the carpenters and the masons. The work of the carpenters was almost wholly temporary. There is little permanent woodwork in a modern skyscraper and the carpenters devoted their energy to such things as chutes, stagings and moulds for concrete. The masons found their stone (Indiana stone

was used in the Empire State Building) all ready raised for them by the cranes, and distributed by the temporary light railway system installed on every floor. This system worked to a timetable which was published daily, so that it was possible, at any moment, to determine exactly where, and in what quantity, supplies of material were being delivered. In the Empire State Building the stonework was begun, not at ground level, but at the seventh floor, the men working downwards as well as upwards. In a skyscraper there is no need to build the stonework up from the ground, as the masonry walls of each floor are carried on the corresponding steel spandrel beams of the frame.

A Self-Contained City

After the masons had got the outer stonework in place, the building began to look more or less complete externally. Almost all the internal work, however, was still to be done. The floors formed, as in all modern steel-framed buildings, of concrete arches between the steel floor beams, went into place soon after the steelwork itself was finished. They were promptly invaded by an army of plumbers (the normal kind this time), steam-fitters, electricians and sheet-metal workers, busy about pipes, conduits, ducts and wiring. Partitions and door-frames were put up, the doors hung and the walls and ceilings plastered Then came the installation of elevators, electric light, radiators, telephones, and air-conditioning plant. There are fifty-eight passenger elevators, and six for baggage, in the main building, as well as two for the secondary tower and one for the observation tower. There were 6,400 windows to be glazed. Sockets for 350,000 lamp bulbs had to be filled.

The Empire State Building was opened to the public on May 1, 1931, less than two years from the start of the demolition of the old Waldorf-Astoria. Fully occupied, it constitutes a self-contained city of 25,000 people. The total floor area of the building is nearly seventy acres. From the ground level to the top of the dirigible mooring mast crowning the secondary tower is a height of 1,250 feet, to which may be added the 15½ feet of a small mast carrying anemometers and other instruments.

The extreme skyscraper, a commercial building exceeding, say, 500 feet in height, is not to be found outside the United States. On the other hand skyscrapers are not exclusively confined to New York. For example, Detroit has the Greater Penobscot Building (565 feet high); Cleveland, its Terminal Tower (708 feet); Columbus, the American Insurance Union Building (555 feet); Cincinnati, the Carew Tower (574 feet); and Pittsburgh, its “Cathedral of Learning” (510 feet).

Plans have already been prepared for more than one New York skyscraper that will dwarf the Empire State Building. The difficulties which have hitherto prevented the execution of these plans have been financial, not constructional. The RCA Building (in the Rockefeller Center), the only important New York giant of later date than the Empire State Building, is considerably smaller - 850 feet only.

Plans have already been prepared for more than one New York skyscraper that will dwarf the Empire State Building. The difficulties which have hitherto prevented the execution of these plans have been financial, not constructional. The RCA Building (in the Rockefeller Center), the only important New York giant of later date than the Empire State Building, is considerably smaller - 850 feet only.

In a rapidly changing world it is unsafe to assert that anything is assured of a permanent future. But the method of construction suggested by Viollet-le-Duc and first put into practice by William Jenney has revolutionized the building of large structures.

STEEL GRILLAGES, set above the reinforced pillars of the foundations of the Rockefeller Center Buildings distribute evenly the weight of the steel frame. These grillages weighed 13 tons to 31 tons each.

[From part 17, published 22 June 1937]

Click here to see the photogravure supplement to this article.

Click here to see the photogravure supplement to this article.

The cover of part 17 shows the tallest building in the world, the Empire State Building in New York. How this huge structure, 1,250 feet high, was built is described in the chapter above.

NO ocean voyager, however wide his experience, ever forgets his first sight of New York from the sea. As the skyscrapers come over the horizon, he obtains a glimpse of fairyland -

NO ocean voyager, however wide his experience, ever forgets his first sight of New York from the sea. As the skyscrapers come over the horizon, he obtains a glimpse of fairyland -

Buffington’s “cloud-

Buffington’s “cloud-

to being. No one can seriously visualize business men habitually doing what some of the unfortunate New Yorkers have to do during a strike of elevator attendants -

to being. No one can seriously visualize business men habitually doing what some of the unfortunate New Yorkers have to do during a strike of elevator attendants - Not only are the skyscrapers built after 1916 higher than their forerunners, but they are also much more graceful. Before the introduction of the zoning laws, a building of any height whatever might be of exactly the same section throughout. To get the maximum possible value for acreage, it often was built in this way and thus looked ugly.

Not only are the skyscrapers built after 1916 higher than their forerunners, but they are also much more graceful. Before the introduction of the zoning laws, a building of any height whatever might be of exactly the same section throughout. To get the maximum possible value for acreage, it often was built in this way and thus looked ugly. The work of erecting the steel framing of the huge building began in April 1930. The amount of steel used would have provided a complete double railway line between London and Manchester.

The work of erecting the steel framing of the huge building began in April 1930. The amount of steel used would have provided a complete double railway line between London and Manchester. The speed at which the ironworkers ran the main frame together can be judged by comparison of a few dates. On April 7, 1930, the first of the steel columns were set upright in place. These were one story in height and rose out of the concrete and steel “footing”, 35 feet below ground level, set into the rock of Manhattan Island. By the middle of April all the 200 columns had been built up as far as the second floor, and the construction was well under way, material going in at the rate of 10,000 tons of steel a month.

The speed at which the ironworkers ran the main frame together can be judged by comparison of a few dates. On April 7, 1930, the first of the steel columns were set upright in place. These were one story in height and rose out of the concrete and steel “footing”, 35 feet below ground level, set into the rock of Manhattan Island. By the middle of April all the 200 columns had been built up as far as the second floor, and the construction was well under way, material going in at the rate of 10,000 tons of steel a month. Plans have already been prepared for more than one New York skyscraper that will dwarf the Empire State Building. The difficulties which have hitherto prevented the execution of these plans have been financial, not constructional. The RCA Building (in the Rockefeller Center), the only important New York giant of later date than the Empire State Building, is considerably smaller -

Plans have already been prepared for more than one New York skyscraper that will dwarf the Empire State Building. The difficulties which have hitherto prevented the execution of these plans have been financial, not constructional. The RCA Building (in the Rockefeller Center), the only important New York giant of later date than the Empire State Building, is considerably smaller - Click here to see the photogravure supplement to this article.

Click here to see the photogravure supplement to this article.