© Wonders of World Engineering 2014-

Part 22

Part 22 of Wonders of World Engineering was published on Tuesday 27th July 1937, price 7d.

Part 22 includes a photogravure supplement showing the construction of the Birchenough Bridge, in Southern Rhodesia, illustrating the article describing the construction of the third longest single-arch span in the world.

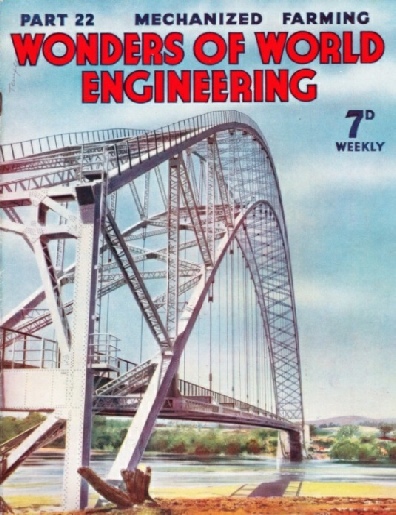

The Cover

The cover this week shows the Birchenough Bridge and is reproduced from a photograph provided by Dorman Long and Company Ltd. The building of this magnificent structure, the thrid longest single-arch span in the world, is described fully in a chapter in this Part. The bridge has a total length of 1,240 feet and the great arch rises to a height of 280 feet above the River Sabi in Southern Rhodesia.

Contents of Part 22

Pioneers in Australia (Part 2)

The story of the construction of a north-south telegraph line and of the east-west the Australian Transcontinental Railway, concluded from part 21.

Electric Lighting Developments

Unremitting research has been responsible for striking improvements in the electric illumination of houses, streets, docks and airports. In this chapter the problems of electric lighting are explored and how they are being solved by research engineers. Second only in importance to the problem of street lighting is that of the illumination of airports at night so that aircraft may identify them and land in safety. How this is done is also described. This is the fifth article in the series on the Romance of Industry.

The Birchenough Bridge

An invaluable link in the communications of Southern Rhodesia is the Birchenough Bridge, across the River Sabi. This imposing steel structure in the heart of Africa is the third longest single-arch span in the world. It was designed by Mr. Ralph Freeman, and built by Dorman Long and Co, Ltd, of Middlesbrough. The Birchenough Bridge is one of the most convincing examples of the way in which the engineer can bring the amenities of civilization into the interior of such a continent as Africa. This chapter is the ninth in the series on Linking the World’s Highways.

The Birchenough Bridge (photogravure supplement)

Contents of Part 22 (continued)

Yarrow Water Tube Boiler

One of the best known forms of water tube boiler is the Yarrow boiler, which is described in this chapter. This is the thirteenth article in the series on Modern Engineering Practice.

Power and the Plough

Agriculture, the world’s oldest and most important industry, has in comparatively recent years been revolutionized by the application of ingenious machinery to its many operations, which include ploughing, sowing, harvesting and threshing. In this chapter are described the ingenious mechanical ploughs that are used in conjunction with agricultural tractors. Among these agricultural machines one of the most ingenious is the mechanical harvester.

Oil Refining in Iran (Part 1)

This chapter deals with the work of a modern oil refinery. The plant in question is situated at Abadan, at the head of the Persian Gulf. Oil is brought to the refinery by pipe line from oilfields more than 100 miles inland. Over 7,000,000 gallons of crude oil are delivered every day to be treated and refined in this huge modern plant, where nearly 11,000 men are employed. This article is concluded in part 23.

The Birchenough Bridge

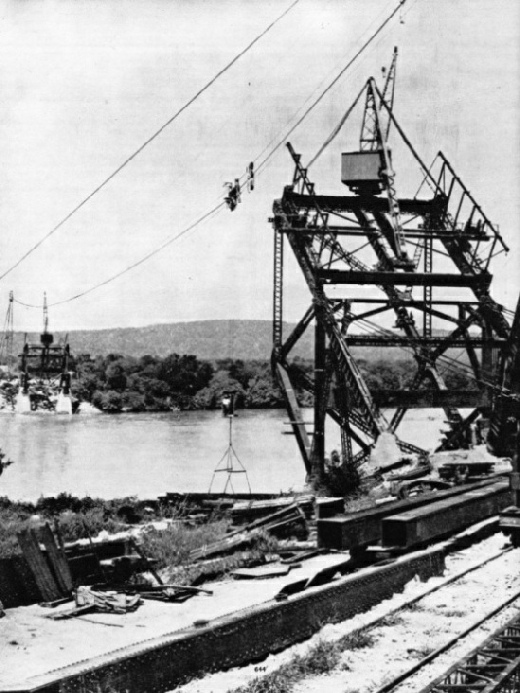

Photogravure Supplement - 3

THE CABLEWAY ACROSS THE RIVER was suspended from two steel towers, 1,400 feet apart. The cableway was used to transport materials and plant across the River Sabi during the building of the Birchenough Bridge. Electric power for driving the cableway and cranes was obtained from two portable generating sets driven by high-speed diesel engines.

The Birchenough Bridge

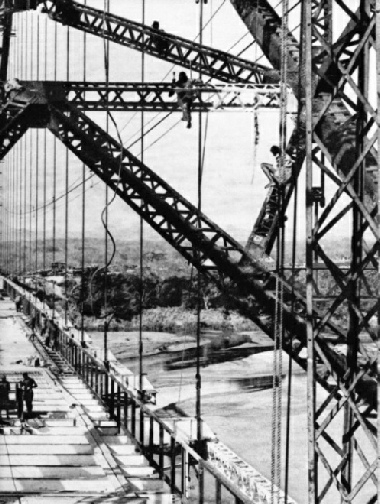

Photogravure Supplement - 2

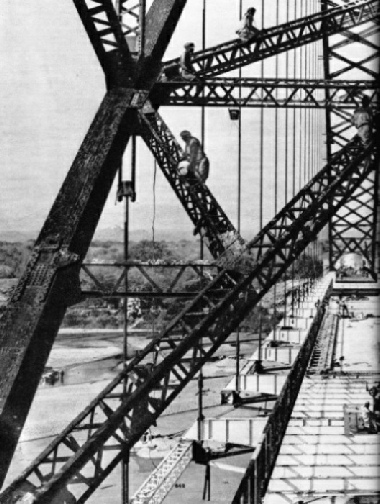

THE ROADWAY along the deck of the Birchenough Bridge is 18 feet wide. On either side of this are the footways. The main cross girders of the deck can be seen projecting from the line of the roadway at intervals of 40 feet. The ends of these girders are suspended from the great arch by steel cables with a diameter of 2¾ in. These cables were used as anchorages suring the building of the arch. The same cables had been used in the building of the Sydney Harbour Bridge. Beneath the roadway and running the whole length of the deck is a huge horizontal truss, 48 feet wide, which keeps the suspended portion rigid against the pressure of the wind.

The Birchenough Bridge

Photogravure Supplement

1,500 TONS OF STEEL were used for the arch span of the Birchenough Bridge. The same amount was used for the Victoria Falls Bridge, which has a span less than half the length. The total length of the Birchenough bridge is 1,240 feet, and the enormous arch rises 280 feet above the River Sabi.