© Wonders of World Engineering 2014-

Part 4

Part 4 of Wonders of World Engineering was published on Tuesday 23rd March 1937, price 7d.

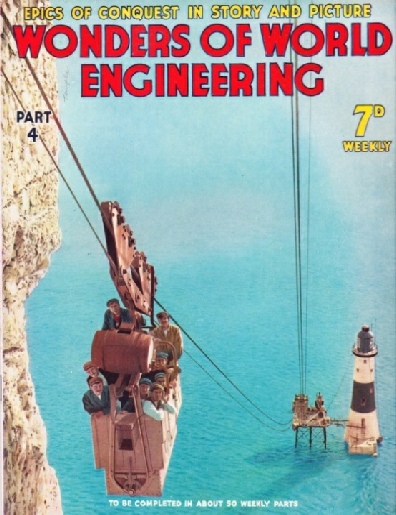

Part 4 includes a colour plate From Cliff Top to the Lighthouse illustrating the article on Sentinels of the Sea. The plate also appeared as the front cover of this issue.

The Cover

From Cliff Top to the Lighthouse: the colour plate accompanying the chapter on Sentinels of the Sea shows workmen travelling on the cableway at Beachy Head Lighthouse. The plate is a reproduction of this week’s cover.

Contents of Part 4

Fighting Famine in India (Part 2)

The story of canals, dams and barrages to help stamp out famine in India. The chapter is the second article in the series on Triumphs of Irrigation. It is concluded from part 3.

Sentinels of the Sea

Extraordinary ingenuity, courage and determination are shown by the engineers who build, in dangerous and difficult conditions, the lighthouses which guide and safeguard ships at sea. Most lighthouses are built on or close to the land, and it might seem that no special difficulties would present themselves when a lighthouse had to be built so near the amenities of everyday life. However this chaptershows that extraordinary ingenuity, courage and determination have been displayed by the engineers who have built some of the world’s most famous lighthouses. This chapter deals also with the technical equipment inside a lighthouse.

From Cliff Top to the Lighthouse (colour plate)

From Cliff Top to the Lighthouse

FROM CLIFF TOP TO THE LIGHTHOUSE, which was built 500 feet from the base of Beachy Head, Sussex, men and materials were transported by a cableway. The original lighthouse at Beachy Head was on top of the cliff, but because the light was often obscured by fog, the new lighthouse was built at sea level. A cofferdam was built on the site, and pumps kept out the water while the tower was being constructed. The lighthouse is 103 feet high.

Contents of Part 4 (continued)

Romance of Motor Car Making

Large-scale production of motor-cars is made possible by the specialization and organization of a vast number of engineering processes. The building of Morris cars affords an excellent example of the methods adopted in the industry. Motor cars are a commonplace of our daily life. Many people use them and all of us see them, but not everyone realizes that modern motor car manufacture gives us material for one of the greatest stories of engineering. This chapter deals with the manufacture of the modern car and the organization of a typical plant. The factory with which this chapter deals is that of Morris Motors, at Cowley, Oxford. Mr W. R. Morris he began his career by supplying and repairing bicycles at Oxford. Then he carried out the experiments which led to the building of the original Morris car and to the remarkable developments associated with his name.

Artesian Wells

In certain parts of the world extensive areas are largely and sometimes entirely dependent on deep-bore wells for their water supply. Such deep-bore wells are called artesian because they were originally supposed to have originated in Artois, France.

Building the Menai Bridges

Although the suspension and tubular bridges over the Menai Straits were built many years ago, they are still classed among great engineering achievements. These remarkable bridges taxed all the skill and ingenuity of their designers, Thomas Telford and Robert Stephenson.

Lapland’s Arctic Railway (Part 1)

Beyond the Arctic Circle in Sweden, engineers have built a railway to open up a valuable natural deposit of iron ore, and Nature has been harnessed to supply the power for the railway. The article is concluded in part 5.