Millions of coins are used annually to operate “automatic” machines for issuing goods, tickets, gas or electricity, or for entertainment purposes. Many of these devices are electrically operated and certain ticket issuing machines not only print the tickets but also deliver the correct change

THE amount of pennies and silver coins that pass through the slots of “automatic” machines annually in Great Britain cannot be computed. Moreover, it is increasing with the growing variety of machines whose mechanism is freed for operation by the insertion of a coin. The machines include meters which allow a measured quantity of gas or electricity to pass, and these slot or prepayment meters receive millions of coins in a year.

Other slot machines are attached to telephones in public call-

Although the slot machines have been improved and developed enormously during the last few years, the idea is ancient. The first slot machine is believed to have been installed in Egyptian temples centuries ago for the purpose of supplying sacred water. The pilgrim or worshipper put the coin into a slot at the top of the machine and it fell on to a lever balanced on a fulcrum. The coin tipped one end of the lever so that the other end, to which was attached a vertical rod, was raised. The rod was submerged in water and at its lower end was a valve which fitted as a lid on the top of a small chamber. When the rod was raised by the falling coin the water flowed into the chamber and out through a pipe. The weight of the rod pulled the lid down again, stopping the flow of water.

Automatic machines which supplied snuff, or sufficient tobacco to fill a pipe, were used in Great Britain early in the last century. About fifty years ago American inventors concentrated on devising slot machines, and even then all-

In the United States inhabitants of large cities accepted the machine as an automatic salesman on duty at all hours, but in Great Britain this attitude is largely the result of laws restricting shopping hours and of improvements in the machines. Although cigarettes have been sold singly from machines for many years, these machines were regarded merely as a convenience. Then an Act was passed compelling tobacconists to close at stated hours, and there were installed machines supplying cigarettes in packets of tens and twenties. Before these machines had become numerous there was a tendency for smokers to tempt shopkeepers to break the law by selling cigarettes after hours, but machines are now so extensively used that they protect the shopkeeper from this annoyance. They meet the need of the person who regards a closed shop door as a barrier to his convenience, and they meet with the approval of social workers who are trying to secure more leisure for shop assistants.

Ticket printing and issuing machines are now extensively used by the London Passenger Transport Board. These machines issue tickets of values ranging from one penny to one shilling; some of the latest designs are equipped with devices for giving change.

Machines worked by copper coins can be operated by inserting either halfpennies or pennies, or both. The coins can be put into the machine in a bunch haphazardly. If the passenger wishes to buy more than one ticket he can insert the total money for the number of tickets simultaneously. He puts in the money and the machine will sort and count it and deliver the tickets. The mechanism is worked by a ¼ horsepower electric motor, set in motion by the coins, which make an electrical contact. The motor is controlled by a clock device which switches it off in from six to eight seconds. Formerly the machines were operated by a continuously running motor. When there is a line of passengers the operation of the motor is continuous, as the coins may be thrust into the machine by one passenger after another so rapidly that it is not necessary for one passenger to wait for the previous passenger’s ticket to be delivered before putting in the coins. A queue can thus move steadily forward, and the speed of a change-

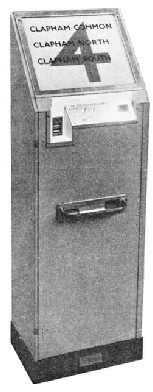

TICKET ISSUING MACHINE of the type extensively used in London underground stations. The machine prints the tickets as soon as the necessary coins have been inserted. Change and rejected coins are delivered in the receptacle halfway down the machine.

Change-

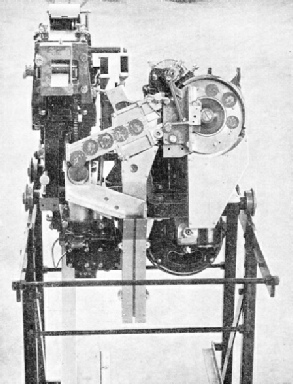

Each machine prints its tickets from a plain roll of paper which can be replenished in half a minute or less. The paper tickets cost less than cardboard ones, and they eliminate the necessity for keeping and checking a stock of printed tickets which have a definite value immediately they are printed. The printing can be done on one or both sides of the ticket, and the date and serial number can be included. The blank roll of ticket paper provides from 2,000 to 4,000 tickets, according to the length required for each ticket.

The change-

Copper and silver coins are automatically stored in the change-

The machine is enclosed in a sheet-

The printer is simple, robust and of the rotary type. The number of printing rollers varies according to the amount of typematter required on each ticket, and whether it is to be printed on one or on both sides. If necessary the printing rollers can be removed and replaced by others in a few seconds. A counter on the printer box records the number of tickets issued, and this counter cannot be altered when the printer box is out of the machine except by completely dismantling it. As the whole is sealed it cannot be opened by unauthorized persons without detection.

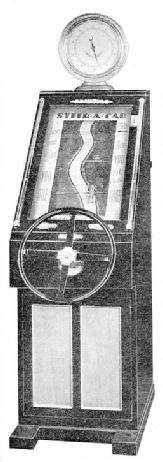

OPERATED BY ELECTRIC MOTORS, the “Steer-

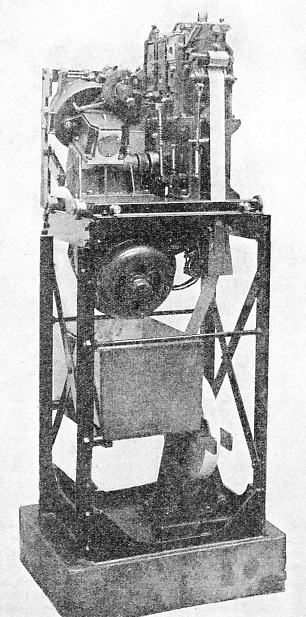

The coin mechanism which operates the printer is also of unit construction. On the change-

When coppers are dropped into a bunch hopper they switch on the mechanism and are tested and counted. They fall upon a disk which is revolved by an electric motor and bevel gearing. They are caught by studs on the face of the disk and are carried round in a counter-

The rim of the counter wheel has teeth set at intervals, each tooth being spaced in accordance with the value of the ticket. In a machine for fourpenny tickets, each halfpenny moves the disk one-

Rejected Coins

When the disk has turned the distance ensured by the value of the coins, the tooth engages a pawl attached to a connecting rod and forces it downwards. In turn the connecting rod operates a clutch release pawl which engages a clutch disk. This is part of the first actuating wheel which operates the printer by means of gears and a driving shaft. The strip of paper or cardboard passes between the pressure rollers, is printed, cut by a knife on a cutting roller and delivered to the passenger.

Thus the tooth on the counter wheel starts the printing and delivery of one ticket when the last coin has passed the trip lever. The coins pass on down a chute to the cash till in the bottom of the case. If a coin is bent or battered it will not be retained by the studs on the disk, and will slip out and down the chute for rejected coins.

In vending machines delivery is effected by various types of mechanism. In these machines the coin-

The modern vending machine generally contains an electric clock or an electric sign, and is also lighted by electricity. The lighting is controlled by an automatic time switch in the base of the case, and this switches the current off at any predetermined time. The case is of stainless steel, the glass is armour-

Some machines are built in the door of a shop, to save space. The vending machine is built into the woodwork of a new door and the entire door replaces the ordinary door of the shop. Another type of machine is placed on the counter of a shop or on the desk in the reception hall of an hotel, and is operated either by coins or by the assistant. It is not a change-

Huge sums of money pass through the slots of prepayment gas meters. There are various types, including one which is available for either a penny or a shilling, to prevent the householder from being inconvenienced should he not have the one coin available. The meter works in an analogous manner to the steam engine, the pressure of the gas operating the recording mechanism. Instead of pistons there are two leather diaphragms made from the skin of an animal. Each diaphragm drives a D-

The meter is divided into two sections, upper and lower. The upper section contains the valve gear driven by the diaphragms and is connected to the recording mechanism, and also contains the prepayment mechanism. The lower section is divided into four measuring chambers, two opposite each diaphragm. While gas is flowing into one diaphragm it is flowing out of the other, so that there is no interruption in the supply and the flow. When a coin is put into the slot it presses down a lever on to a toothed wheel. The householder turns the wheel from the outside and the rotation operates a cam. If a penny is inserted the drive to the cam is direct, but a shilling operates another toothed wheel geared 12 to 1, so that a shilling turns the cam twelve times as far as a penny. This cam operates the valve which allows the gas to pass. When the amount has been delivered the cam, which is worked by a drive inside the meter, shuts the valve.

Attention to dieting has benefited the makers of coin-

OPERATED BY COPPER COINS, this mechanism is used in ticket-

When a person steps on to the platform of the machine the momentum at first causes a gramophone needle to wobble over the blank gap in the record, but the needle steadies. Then the penny is inserted, and this closes an electric circuit and starts the motor which revolves the disk once. As the disk begins to turn, the needle falls into the sound groove corresponding with the weight measured by the weighing platform. The record turns at about half the speed of the usual gramophone and this enables the reproduction into sound through the soundbox to be slow enough for the hearer to understand it clearly. Disks are manufactured with sound tracks in many languages.

In weighing machines which print the weight on a cardboard ticket, type is mounted on the rim of a wheel. The wheel turns in accordance with the weight of the person on the platform of the machine and pauses under a stamping device which presses a ticket on to the type and discharges it down a delivery chute.

Many ingenious machines are made for amusement purposes. Most of the newer models are worked by electricity. The general principle of these machines is that when the penny is inserted it closes an electric circuit which enables current from external wiring to flow to electric motors of one-

One machine of this kind is the “Rotary Skill Merchandiser”. It consists of a glass-

The table is set in motion by an electric motor, and a coin is placed in the slot and passes to a catch which is operated by the control lever connected with the top of the cabinet. This lever operates the rod which passes across the table. When the lever is pressed a catch is released and the penny falls to a stop where it closes an electric circuit. The current passes to the motor which operates the rod by gears, and the rod is pushed across the table. At the end of the rod’s sweep the catch holding the penny opens, releasing the coin, which falls into a receptacle, and the circuit is broken.

Another machine is called the “Pile Driver” and includes a drum containing twelve receptacles in which articles are placed. The operator inserts a coin and then pushes a lever and tries to time the working of the “pile driver” so that it descends and pushes an article out of a receptacle into a chute.

Other machines are operated by rollers turned by electric motors. The “Steer-

Large numbers of machines are operated mechanically and not electrically. Other machines are operated mechanically, but have devices for recording scores by electricity.

THE PRINTING MECHANISM of a ticket issuing machine is set in operation when the necessary number of coins has been inserted. A strip of paper from a roll moves forward between printing rollers and is automatically guillotined and delivered.

A walk on a seaside pier will indicate the fashions in amusement machines. At one time they were built of iron and were painted in gay colours; then fashions changed and electrically-

These machines present some problems to the designer which are not encountered in other branches of engineering. Many difficulties had to be overcome to obtain mechanism that could be put into operation by the insertion of coins and would reject spurious coins.

The fact that the coins in circulation vary considerably in weight, thickness and composition prevents the fining down of the coin selector to narrow limits, and a margin therefore has to be allowed.

Many inventions have been made to test silver coins. In one the coin is subjected to an alternating magnetic field produced by a thermonic valve oscillator. The change in frequency of the oscillator due to the currents created in the coin is compared with that produced in that oscillator or a similar one by a standard coin, and if there is a difference the coin is rejected.

Machines have been made to be operated by the twelve-

You can read more on

on this website.

You can read more on

in Railway Wonders of the World