The rolling lift bridge is a form of bascule bridge, the characteristics of which are simplicity of working and inexpensiveness of construction

160-FOOT SINGLE-LEAF DOUBLE-TRACK SCHERZER ROLLING LIFT BRIDGE ACROSS THE CUYAHOGA RIVER AT CLEVELAND, OHIO, U.S.A., IN CLOSED POSITION. This view shows the manner of mounting and operating it on a steel tower 70 feet high. This bridge has been duplicated by the Soudan Government for a crossing over the Nile.

SPANNING a river is always a problem of considerable moment to the railway engineer; there are so many factors to be borne in mind. Not only is he forced to keep the essential and rigid requirements of the steel highway to the forefront, but he is compelled to fulfil the demands of other interests. The issue is aggravated in its complexity when the crossing is over a busy waterway, in a congested city or town, and when the banks are somewhat low-lying. The claims of navigation have to be regarded, often to the disadvantage of other methods of transportation.

In meeting such different conditions, the engineer has displayed considerable ingenuity. Three methods of meeting the situation are available - tunnelling beneath the waterway, installing a train ferry, and bridging. The first is impracticable, except in rare circumstances, from motives of cost and the difficulty of flattening the approaches to the subterranean highway sufficiently to secure easy, economical movement. The second generally is not feasible, as it entails serious delays. Bridging, therefore, remains as the solitary expedient, and this is the solution invariably adopted.

Here again, however, difficulties arise. What is the type of bridge most suited to the prevailing conditions and able to meet to the best advantage the claims of both railway and navigation? This is an issue which cannot be decided without the most minute investigation. The bridge may be built at a sufficient height above the waterway to afford adequate headroom to the traffic passing beneath, but in this event the natural contour of the land must be propitious to the provision of the approaches, unless expenditure is a secondary consideration. If these favourable conditions do not prevail then the engineer must provide some means of interrupting the railway link when and as required in coincidence with marine requirements.

This end may be fulfilled in many ways. The engineer may introduce a vertical lift method as described in the chapter “A Telescopic Double-Lift Bridge”; a swing bridge, the solution which has met with the widest approbation hitherto; or a bascule system similar to that adopted in connection with the Tower Bridge, across the Thames, which principle has come into somewhat extensive vogue during recent years.

The bascule bridge probably is one of the oldest bridge-forms known. In the Middle Ages, when castles and moats were the fashion, it was known as the drawbridge, but with the advent of modern civilisation it fell into desuetude. It was only when railway and navigation interests came into conflict that it underwent revival, and has received its most powerful illustration in modern times in the Tower Bridge.

About eight years after this monumental work had been commenced, an American engineer, William Scherzer, conceived a new type of bascule bridge, the salient features of which were greater simplicity, both of design and operation, extreme cheapness in installation, maintenance and working, and enhanced speed in operation. The invention aroused instant attention, as its engineering features were too pronounced to be ignored. In some quarters the claims of the inventor were criticised, but the opportunity arose whereby he was able to demonstrate the practicability of his idea, and to establish his contentions in no uncertain manner. The Metropolitan West Side Elevated Railroad desired to get into the business centre of Chicago, but was faced by the Chicago River. The company wanted to lay down four roads, for which the right of way had been secured. This extended between two existing swing bridges, and although the railway company at first concluded that the swing bridge would meet their requirements, they found it impossible to adopt this solution, for the simple reason that there was no space in which to place the structure, as the existing bridges were too close together.

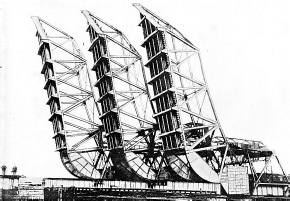

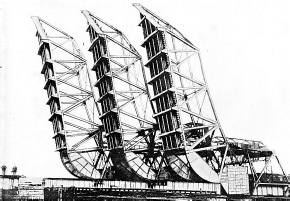

160-FOOT SINGLE-LEAF DOUBLE-TRACK SCHERZER ROLLING LIFT BRIDGE ACROSS THE CUYAHOGA RIVER AT CLEVELAND, OHIO. U.S.A. This view shows the bridge open. The front part is 255 feet above the water.

160-FOOT SINGLE-LEAF DOUBLE-TRACK SCHERZER ROLLING LIFT BRIDGE ACROSS THE CUYAHOGA RIVER AT CLEVELAND, OHIO. U.S.A. This view shows the bridge open. The front part is 255 feet above the water.

As a solution of the difficulty, an eminent American engineer suggested that a bridge, similar in character to the Tower Bridge and working upon the same principle, should be adopted. The authorities acceded to the proposal, and the plans were taken in hand. As the latter matured, however, certain drawbacks were observed. At last the railway management called in Mr. Scherzer to determine whether his new idea was applicable to the situation, and, if so, would it be suitable to the purposes demanded. Time was pressing, since the remainder of the track was almost completed. Mr. Scherzer had been turning over in his mind the possibility of evolving what he termed “a rolling lift system”, and he saw that it could be incorporated in this case very efficiently, so he prepared plans in accordance with his ideas. The first designs were submitted to the management, and they were so impressed with its advantages that they placed the contract in his hands.

The bridge is, in reality, in two sections. Two duplicate structures, each carrying two sets of metals, are built side by side, and firmly coupled together so as to be operated as one bridge. Inasmuch as it might be desired to use each section separately, the designer introduced facilities whereby, within ten minutes, the coupling can be severed, and each bridge operated independently of the other, so that, the railway has a crossing at all times. The movable span is 114 feet, centre to centre of bearings, and the channel between the masonry piers is 108 feet. This structure is designed to act upon either the arch or cantilever principle. When acting as a cantilever the live load is supported by the tail girders, which are locked under the projecting approach spans, the latter being firmly anchored into the masonry. The counter-weighting is so carried out that upon opening the tail and centre locks, the leaf rises to an angle of about 30 degrees, so that only the minimum of energy is required to open it still wider or to close it. As a rule, the bridge can be opened or closed within thirty seconds, and is ready to permit trains to pass within a minute of its commencing to close.

TWO SINGLE-LEAF SCHERZER ROLLING LIFT BRIDGES, MOUNTED SIDE BY SIDE, OPERATED FROM OPPOSITE BANKS. Each bridge carries two sets of metals. This photograph shows the rolling segment and elevated side counter-weights.

This particular bridge constituted a severe test for the new idea, inasmuch as the Chicago waterway is very busy, while the railway traffic is heavy. On the average, 1,200 trains cross the bridge during the twenty-four hours, while the bridge itself has to be opened about forty times a day to permit vessels to pass. Rapid working in this instance was of paramount importance, so that the railway traffic might not be hindered more than was absolutely necessary. Experience has demonstrated very conclusively the many advantages of this type of bridge. In fact, the railway company were so impressed with its superior features that immediately afterwards they approached the civic authorities and received the requisite permission to convert the adjacent swing bridge to the Scherzer Rolling System.

Another illustration of the possibilities of the system Avas furnished also in the same city, and this example served to show how economically such a structure can be built and operated. The Chicago Terminal Transfer Railroad Company selected the system in order to provide them with access to the Grand Central station. The design called for a clear opening of 255 feet between the piers - 55 feet more than the opening of the Tower Bridge. In the latter structure the total weight of iron and steel is about 14,000 tons; it has a capacity of some 5,000 pounds per lineal foot of bridge; the total moving load on the shafts of the pivot whereon the leaves move is 2,400 tons; while two hydraulic engines, each of 360 horse-power, are required for operation. In this particular Scherzer bridge the total weight of the metallic parts is only 2,250 tons; it has a capacity of 10,000 pounds of moving load per foot of bridge - twice that of the Tower Bridge. The total moving load is only 1,773 tons; while two 50 horsepower electric motors suffice to operate it. This Chicago bridge was erected complete for £25,200 - less than the expenditure involved in connection with the hydraulic machinery alone of the Tower Bridge. This Scherzer bridge has the longest movable span yet provided upon this system. The leaf is 275 feet in length, and has to be opened occasionally as many as 100 times a day.

Needless to say, this very marked difference served to emphasise the possibilities and economy of the Scherzcr Rolling System in no uncertain manner. Therefore it is not surprising that engineers recognised that in this invention they were offered a complete solution of the difficulties which harass them under such conditions from time to time. The various railways running into Chicago which were forced to cross the navigable waterways embraced the idea; while the civic authorities, on their part, recommended the bascule bridge because it rendered a wider navigable channel available to the busy maritime traffic.

FOUR SINGLE-LEAF DOUBLE-TRACK SCHERZER ROLLING LIFT BRIDGES, SIDE BY SIDE, FORMING AN EIGHT-TRACK STRUCTURE ACROSS THE SHIP CANAL, CHICAGO. This is the widest and heaviest bascule bridge in the world.

It may be pointed out that the Scherzer is by no means the only expression of the bascule bridge of to-day, but it was the first to be operated upon the rolling lift principle. The idea is very simple. If one takes a wheel and divides it into four equal parts, and then sets up one of these segments vertically upon a horizontal runway, forming a track as it were, and upon the upper side lays a plank horizontally, so as to overhang in the form of a leaf, one has the Scherzer bridge in its most primitive form. Now if one presses down the tail end of the leaf the segment will run backwards in the manner of a quadrant, causing the leaf to swing up through the air until it is vertical, the tail end then resting upon the ground or dipping into a pit. Such is the basic principle of the Scherzer bridge and its operation, and it is the simplest form of bascule which has been designed yet. In fact, extreme simplicity was the point for which the inventor strove, and in this quest he succeeded completely. Of course, in perfecting the idea from the foregoing nucleus, other mechanical details were taken into consideration, so that the essential movements might be made with the minimum of friction.

The idea can be adapted to meet any requirement. It can be worked upon the double-leaf principle, similar to the Tower Bridge, in the case of wide waterways such as a river, or when spanning a canal a single leaf can be used. In any event, the full width of the waterway can be left free for boat traffic. The bridge can be made as wide as desired or a number of similar structures can be disposed side by side and coupled together so as to be operated as a whole or left detached and independent. Similarly, the idea is as applicable to double as to single-deck bridges, where the exigencies demand the use of one level for railway and the other for vehicular business.

Counter-weighting can be carried out upon such lines that the centre of gravity falls in the centre of the rolling segment. In this case in moving the bridge it is only necessary to overcome the resistance due to friction. By such an arrangement, directly the interlocking devices are withdrawn, the leaves will rise slowly until they assume an angle of 40 degrees, the backward rolling and upward movement being secured without any power whatever. The application of power to open the bridge still wider is very slight, and then, when the moment arrives to close the bridge, the counter-weight, forming a pendulum as it were, swings slightly

in the opposite direction, until the leaf has descended below the 40 degrees mark, when, the power being brought in once more, the bridge is returned to its horizontal position. One advantage of this method is that should anything go wrong with the mechanism the leaf cannot fall from its elevated position. The energy consumed in operating the bridge is so small as to be a negligible quantity; indeed, it is so low that in many instances the authorities working the bridge do not trouble to levy charges for the opening operation.

So far as construction is concerned, interference with the navigable channel is reduced to the minimum. The leaf is erected in the vertical position, and upon completion is swung, to be taken up by the operating machinery. While the majority of bridges of this type which have been built up to the present are designed for utilitarian purposes purely and simply, it can be adapted to any artistic requirement that may be desired, so that aesthetic considerations need not necessarily be ignored.

Some remarkable bridges have been carried out upon this principle, especially in the land of its origin. The New York, Newhaven, and Hartford Railroad was presented with a puzzling proposition when it essayed to improve the facilities for entering and leaving the huge South Terminal station at Boston, Mass. The banks on either side of Fort Point Channel are low-lying, the waterway is busy, the tracks had to be compressed into six, and the engineers were pushed for room owing to the close proximity of swing bridges. Moreover, in order to cross the waterway it was necessary to run at a very acute angle. The situation was discussed very carefully owing to the strict character of the limitations, but at last it was decided to instal a six-track Scherzer rolling lift bridge in three sections, duplicates of one another, two roads to each, and to be coupled so as to be operated simultaneously or independently. This was the first six-track bridge to be built upon this principle, but in operation it has proved completely successful. A 50 horsepower electric motor is sufficient to operate each double-track span of 144 feet, while the whole bridge is controlled and worked by one man.

275-FOOT DOUBLE-LEAF DOUBLE-TRACK SCHERZER ROLLING LIFT BRIDGE ACROSS THE CHICAGO RIVER AT THE ENTRANCE TO THE GRAND CENTRAL STATION. CHICAGO. This is the longest double-leaf bascule bridge in the world.

Another large installation, unique at the time, was the building of an eight-track bridge in order to cross the Chicago Drainage and Ship Canal. In this undertaking three railway companies were concerned, and their lines all run side by side. Consequently when the question of crossing the canal arose, they co-operated. At first it was decided to provide a swing bridge 399 feet 2½ inches in length by 110 feet wide, mounted on a turntable 78½ feet in diameter. Six tracks, were to be laid upon the inside of the bridge, while one was to be provided on either side of each truss, the floor beams being extended for the purpose. Ultimately, however, the railway authorities informed the Trustees of the Sanitary District of Chicago, who were footing the bill, that they could not accede to the proposed plans, because, in the event of a mishap to the bridge the whole of the eight roads would be blocked, while, owing to the constriction of the navigable channels on either side of the central pier whereon the turntable was to be mounted, large vessels would have to proceed slowly and carefully, and thus the interval of interruption to the railway traffic would be extended unduly.

Thereupon the authorities advertised for fresh designs, and the Scherzer proposal was selected out of seven submitted plans. Furthermore, the company operating the patents offered to complete the structure for £68,428. These plans meeting with the unanimous approval of the authorities and railways, the contract was placed. The bridge comprises four through spans placed side by side and in duplicate, each carrying two sets of metals. This is the most ambitious example of Scherzer bridge building that has been attempted. At this point the waterway is 894 feet wide, but 120 feet clear was considered to be adequate for navigation purposes, and so the foundations for the rolling lift spans were set out into the river, the approaches on either side being carried over deck truss spans. The bridge, set at an angle of 63 degrees to the centre line of the waterway, has an over-all length of 1231 feet, each section carrying two roads, being 29 feet wide.

The invention has met with approval among British engineers. The late Sir Benjamin Baker, the eminent engineer and designer of the Tower Bridge, was the first to introduce it into England by installing such a bridge across the River Swale for the South Eastern Railway.

THREE SINGLE-LEAF DOUBLE-TRACK SCHERZER ROLLING LIFT BRIDGES, FORMING A SIX-TRACK STRUCTURE SPANNING FORT POINT CHANNEL AT BOSTON. MASS. Either leaf may be opened independently if desired.

You can read more on

on this website.

160-

160-