© Wonders of World Engineering 2014-

Part 24

Part 24 of Wonders of World Engineering was published on Tuesday 10th August 1937, price 7d.

Part 24 includes a photogravure supplement showing the manufacture of steel, which illustrates the article Steel - From Ore to Ingot .

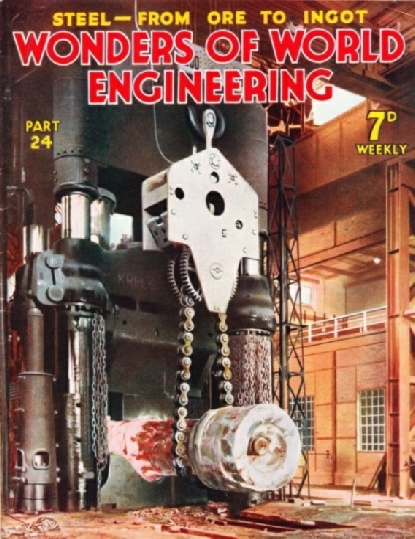

The Cover

The cover this week gives a striking picture of a forging being shaped in a hydraulic press, a method which has largely displaced the steam hammer for heavy work. This press can exert a pressure of 15,000 tons. The photograph was taken in a modern steelworks at Dortmund, South Germany.

This cover was later reproduced as the colour plate issued with Part 46, illustrating the article on Steel - From Ingot to Plate .

Contents of Part 24

British Empire’s Longest Tunnel (Part 2)

The story of the construction of the Otira Tunnel, which took fifteen years to build through New Zealand’s Southern Alps. This chapter is concluded from part 23. It is the sixth article in the series Below the Surface.

Destruction of Refuse

The disposal of the refuse of a large industrial town is a problem that has been treated in a variety of ways. In many place rubbish is now burnt in specially designed furnaces and used to generate electrical power. The story of refuse destruction may not appear to be particularly romantic, but it is one of tremendous importance, and modern methods adopted for disposing of all kinds of refuse and rubbish - from clinkers to tin cans - represent an engineering feat of no mean order. This chapter describes up-to-date methods of refuse destruction.

Steel - From Ore to Ingot

By the addition or elimination of various elements iron ore can be converted into steel of almost innumerable kinds. The processes by which steel is manufactured are among the most spectacular in engineering. It was the invention of the Bessemer converter in 1885 that revolutionized the manufacture of steel, but the Bessemer plant is not much used now in Great Britain. Its great rival, the open hearth furnace, was the invention of a British engineer, Sir William Siemens, although it was improved by the brothers Martin, of Sireuil, France. The Siemens-Martin furnace came into use in 1863 and is of enormous importance to-day.

Steel - From Ore to Ingot (photogravure supplement)

Contents of Part 24 (continued)

Sir Joseph Whitworth

A pioneer of law and order in the mechanical world, Sir Joseph Whitworth raised accuracy in engineering to a new standard. His name is universally associated with the Whitworth screw thread, and he made many other striking contributions to engineering science. This is the ninth article in the series on Makers of Engineering History.

Explosives and the Engineer

This chapter describes not only the types of work for which explosives must be used, but also the intensely interesting way in which simple substances, harmless in themselves, may be combined to produce some of the most dangerous compounds known to man. Materials latent with devastating power have been brought completely under control, and when we honour the engineer for the magnificent work that he carries out with the aid of explosives, we must give, also, full credit to the chemist for making possible the work of the engineer.

Reclaiming the Pontine Marshes (Part 1)

Four large towns, more than two thousand farms and homesteads and a great network of modern motor roads now occupy what was once a swampy Italian wilderness with an area of 180 square miles. Close to the gates of Rome there is a vast area known at the Pontine Plain. Early attempts to reclaim the Pontine Marshes came to naught, and it was reserved for Italy, under the guidance of Signor Mussolini, to achieve this task. Canals, pumping stations and roads were built, and new towns were founded. This great work is described in this chapter, which is concluded in part 25.

Steel - From Ore to Ingot

Photogravure Supplement - 3

THE BESSEMER CONVERTER is a large steel flask pivoted at the centre so that its mouth can be directed upwards or to the front. Molten iron is poured in and a blast or cold air causes the iron to become hotter by causing combustion in the presence of oxygen. First, the silicon burns and causes a red flame and brown smoke. When the carbon burns, a long jet of bright flame issues from the mouth of the converter. When the carbon is completely burnt, the flame disappears with remarkable suddenness. When the “blow” is finished, the converter is pivoted to the front and the metal is poured as shown in the colour plate shown in an earlier chapter.

Steel - From Ore to Ingot

Photogravure Supplement - 2

OPEN HEARTH FURNACES for the manufacture of steel, invented by Dr C William Siemens and improved by the brothers Martin, came into use in 1863. The open hearth furnace is a large closed chamber with a shallow saucer-shaped bed for the metal. At either end are ports for the admission of hot air and gases which form the fuel and burn over the surface of the metal. Furnaces of this type have a capacity of as much as 300 tons. The molten steel is poured from the furnaces into huge ladles handled by overhead cranes, as shown.

Steel - From Ore to Ingot

Photogravure Supplement

MOLTEN IRON for conversion into various classes of steel is tapped from the cupolas (or small blast furnaces) in which pig iron is melted. This photograph was taken in a steelworks at Letchworth, Hertfordshire. Steel castings are made here and more than 1,500 men are employed.